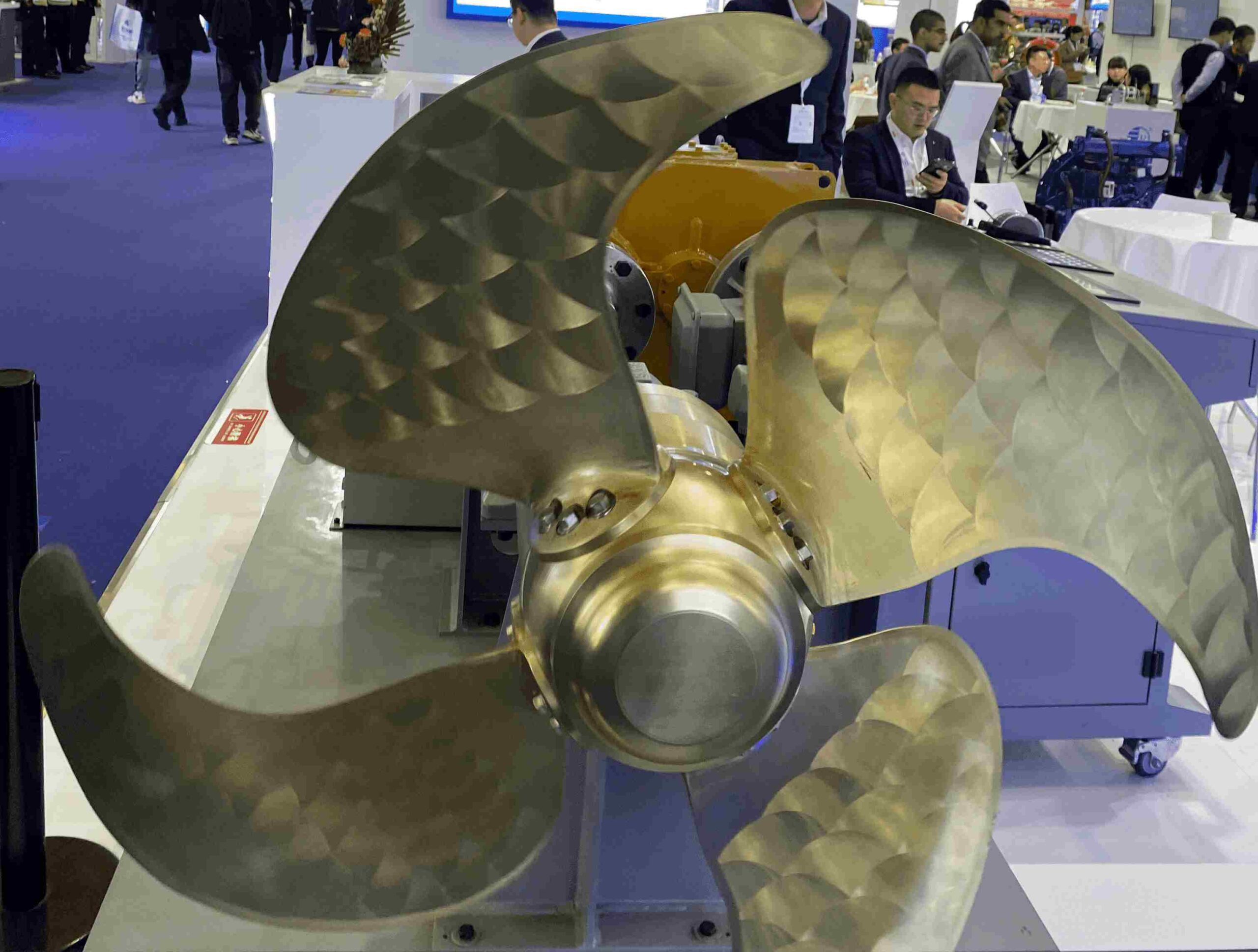

Ocean Propeller & Marine Propeller

Boat motor propeller is a rotating fan-shaped structure attached to the hub by blades. The blade surface is spiral or similar in shape. As a result of their high efficiency and good hydrodynamic performance, ship propellors have always been the first choice for ship propulsion, and their performance directly affects the ship.

Vessel propeller working in the non-uniform flow field, due to the heterogeneity, the flow field in the process of boat propellers functioning, cavitation appears on the blade easily, which causes the violent vibration of the stern, leading to propeller cavitation erosion, causing the harmful effects such as noise. Thus, both the propeller’s blade efficiency, cavitation, vibration, denudation, and other performance factors need to be considered during the design phase.

To increase the reliability of ship performance, it is essential to choose a marine propeller manufacturer that offers qualified and guaranteed propellers.

The standards of our propellers for boats: International Association of Classification Societies (I.A.C.S. )

High-Performance Boat & Ship Propeller for Sale

Our company has the research and design capabilities for fixed-pitch ship propellers, controllable pitch propellers, adjustable propeller blades and propeller hubs, and can also provide the production of various propulsion system products such as paddle fin cap. Gosea marine can also provide diversified marine propeller products of different materials such as Copper alloys, Stainless steel, Nickel-based alloys, Carbon fiber/composite materials,etc.

Vessel Propeller Certifications

Our company has passed ISO9001 quality management system certification and has been recognized by major classification societies such as CCS, LR, DNV, LR, BV ABS, and IRS.

- We can produce A propeller with diameter of 9.6m and weight of 50T for large-scale bulk cargo ship propeller.

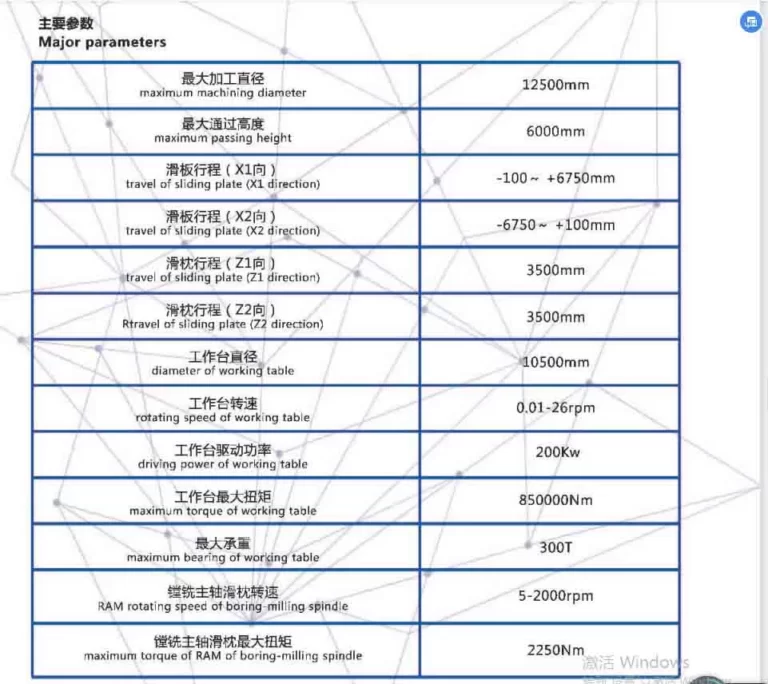

In order to ensure product quality and delivery time, the factory has introduced advanced production and processing equipment from Germany. Our equipment has a maximum processing diameter of 12.5m; a maximum passing height of 6m; a workbench diameter of 10.5m; a maximum load-bearing capacity of 300 tons; and a processing accuracy higher than 0.01mm. Providing customers with high-quality products is the pursuit of Gosea Marine.

Vessel & Ship Propellers Types

In order to improve performance of propeller for boat, better adapt to sailing conditions and make full use of main engine power, the following special propellers were developed based on ordinary propellers.

Controllable Pitch Propeller

It is possible to adjust the pitch of the ship to maximize the power of the main engine; this improves propulsion efficiency, and the rotation direction of the main engine is not changed when the ship reverses. In fishing boats and tugboats, controllable pitch propellers offer better adaptability to changes in blade loads. In contrast, the diameter of the hub of the controllable pitch propeller is much larger than that of ordinary propellers, and the section of the blade root is thick and narrow. Its efficiency is lower than that of ordinary constant speed propeller under normal operating conditions, and it is costly and complex to maintain.

Kort Nozzles and Ducted Propellers

A circular duct with a wing-shaped section is added to the outer edge of an ordinary propeller. Known as a fixed tube, the tube is fixed to the hull and serves as a rudder blade, as well as being connected to the rotating rudder stock. A duct boat propeller can increase propulsion efficiency, but its reverse performance is poor. Ships with a fixed duct propellor have a larger turning diameter, and ships with a rotatable duct propeller have improved turning performance.Ducted propellers are mostly used to push ships.

Tandem Propellers for Sale

Put two or three ordinary propellors on the same shaft and rotate them in the same direction. The restricted diameter of the propeller can increase the area of the blades and absorb more power, which is beneficial for damping vibrations or avoiding cavitation. It is more difficult to arrange and install tandem propellers, and the shaft extends further. Tandem propellers have fewer applications.

Boat Screw Propeller Production Process

Contrarotating Vessel Propeller

Two ordinary vessel propellers are mounted on concentric inner and outer shafts, rotating in opposite directions at a constant speed. Despite its slightly higher efficiency over a single propeller, its shafting structure is complex and has not been used on large ships because it reduces the wake rotation loss.

Nonetheless, the mechanism is extremely complex, pricey, and prone to blade damage, so it is used only for a few harbor ships or ships that have a lot of special handling needs.

Modular Mode

Pitch plate is necessary for scrapping spiral surface in the sand mold processing, and its accuracy directly affects the finished product quality of the blade. When determining the size of the pitching plate, we will consider the pitch of the blade, shrinkage of casting material after pouring, bench thickness, and geometric characteristics of the propellor.

Mold Casting

The vessel propeller is cast with a sand-blasting mold, the surface of the propeller is located below the mold, and the back is located above the mold. For sand molding, first complete a suitable cylindrical surface with a triangular pitch plate, and then use a scraper to obliquely scrape the spiral surface along the axis of the spiral plate. Only one scraper is needed. Through radial linear pitch and pitch, a pair of scrapers are added to the equidistant blades. Then the molten alloy is poured into the mold.

Propeller Processing

Process: cut off the pouring gate, riser, both ends of hub and shaft hole processing, insert the hole into the keyway, scrape the shaft hole, process the blades on the leaf and back, and conduct balance experiment. When processing the risers, gates and other parts at the front and rear ends of the hub, create two datum points at the front and rear of the hub and then drill holes along the hub center and in the hole groove. Boring can be carried out on a lathe or boring machine. Some large blades can also be processed with self-made vertical or horizontal boring rows. Generally, a model or sample shaft will be prepared to check the processing quality.

Blade Processing

According to the measure ment of the propeller, draw the routine blade line and chisel it out For the excess part, process the leaves and the back of the leaves. The blade is processed with the blade as the reference plane. After leaf treatment, use it as a reference plane to re-measure the thickness of the blade, and determine the thickness of the metal layer according to the requirements of the drawing. From the back of the blade, the first drilling, the thickness of the metal layer at the drilling depth, the hole of depth, Dig out the tooth surface shape curve and then remove the excess metal layer along the blade.

Propeller for Boat Packaging

Gosea shipping carefully packages the stainless steel propeller. The edge of the propeller is protected by a corrugated board. The whole fuselage is wrapped with plastic film and safely placed in a plywood box to avoid surface damage or corrosion during long-distance transportation.

If you want to know more about marine propellers, you can read Gosea Marine page: Best Knowledge Of Marine Propeller.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com