Marine Bar Grating

Marine bar grating is a specialized type of flooring or decking material composed of parallel bars or crossbars that are welded or locked together at their intersections. It forms a rigid and durable structure with an open grid design, allowing for the passage of air, light, and liquids while providing excellent support and load-bearing capabilities.

Ship Metal Grates: Steel Grate

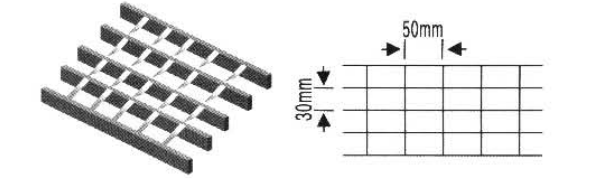

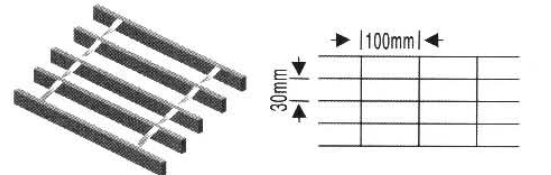

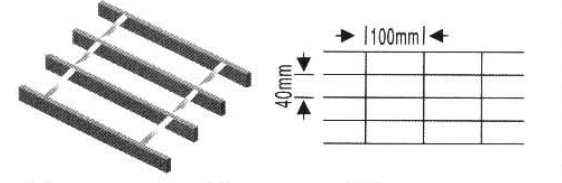

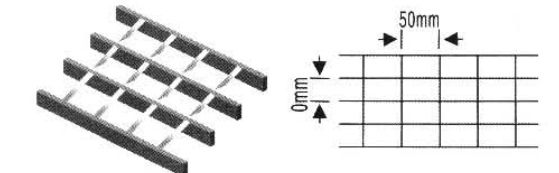

- Spacing:12.5,15,50,30,30.16,32.5,34.3,40,60mm

Marine steel bar grating is a type of metal grating that is widely used in various industrial, commercial, and architectural applications.

The stee bar grating with a flat steel spacing of 30mm is the most widely used variety in the industrial field, and has the strongest resistance to surface impact in the series of commonly used steel bar grating.

The steel bar grating with a flat steel spacing of 40mm is the most economical and lightweight variety. In the case of small span, it is the most ideal choice.

Flat steel spacing of 60mm. The metal grating with 50mm bar spacing is specially developed for the application of the mining industry, which solves the problem of mineral sputtering on the plate surface, and is often designated for the processing plant, transfer station and crushing system of the mining industry.

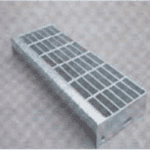

Bar Grating Stair Tread

The marine bar grating stair tread also called floor grate often used for marine ladders , is made of steel grid plate, which is widely used in all kinds of steel structure stairs.The floor grate is convenient to install and maintain, beautiful to lock back and no water accumulation. Floor grate can be customized according to customer needs.

Recommended Floor Grate Width

Type | Width | Width | Width | Width | Width | Width | Width |

T1-T6 Series 1 | 125 | 155 | 185 | 215 | 245 | 275 | 305 |

T1-T2 Series 2 | 125 | 165 | 205 | 245 | 285 | 325 | |

T3-T4 Series 2 | 115 | 155 | 195 | 235 | 275 | 315 | |

T1-T2 Series 3 | 185 | 245 | 305 | ||||

T3-T4 Series 3 | 155 | 215 | 275 |

The Maximum Size Of The Bar Grating Stair Tread

Flat Steel Dimension | 25*3 | 25*5 | 32*5 | 40*5 |

Series 1 | 550 | 900 | 1300 | 1800 |

Series 2 | 450 | 750 | 1200 | 1500 |

Series 3 | 550 | 850 | 1350 |

Types of Metal Stair Treads for Sale

- Type:ZT1

Front guard: No front guard

Installation mode: welded

- Type:ZTF2

Front guard: No front guard

Installation mode: bolting

- Type:ZT3

Front guard: Patterned front guard

Installation mode: welded

- Type:ZT4

Front guard: Patterned front guard

Installation mode: bolting

Bar Grating Stair Tread Bolt Hole Center Distance

Type | Distance | Distance | Distance | Distance | Distance | Distance | Distance |

Bolt hole center distance A | 45 | 75 | 75 | 100 | 100 | 150 | 150 |

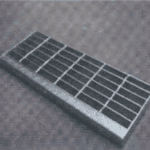

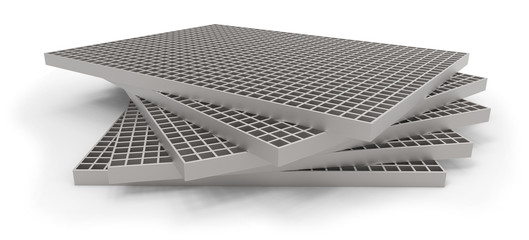

Composite Steel Grating

- Base bar grating material type:FG323/40/100,FG253/30/100,FG323/60/100

The patterned composite steel grating is commonly used with a thickness of 3mm. However, according to customer requirements, it can also be made using 4mm, 5mm, or 6mm thick plates.

The marine composite steel bar grating often used as marine gangway is composed of a pattern plate on the sealing surface and a steel grid plate with a certain span ability.

Composite metal grating after hot dipping zinc treatment, due to thermal stress will produce warping deformation, especially the selection of larger models of steel grid, leveling is more difficult, please pay attention to selection.

Composite Steel Grating For Sale

Numbering | Type | Specification | Quantity | Remark | ||

Special-shaped plate | Length | Width | block | |||

A1 | FF3(FG253/30/100) | / | 900 | 993 | 1 | Galvanize |

A2 | FF5(FG323/80/100U) | Special-shaped plate | 800 | 993 | 1 | Not process |

Marine Stainless Steel Grating

- Material Type:304,316,301

Suitable Enviroment

- The marine stainless steel grating use of harsh environment, need acid, alkali corrosion occasions (such as chemical plants, environmental protection equipment, etc.).

- Occasions with high hygiene requirements “pharmaceutical, food processing”.

- Stainless steel plate occasions with high appearance requirements (such as shopping malls, landscapes).

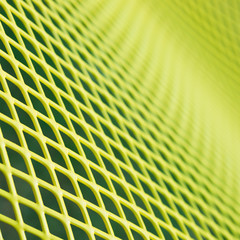

Ship Fiberglass Grating

- Material:Polyester resin

- Standard:Comply with ASTM(American Society for Testing Materials)E-84 standard Fire Class 1, indicator 25 or lower ethylene resin/Comply with ASTM(American Society for Testing Materials)E-84 standard fire Class 1, index 25 or lower carbonated resin

Marine fiberglass grating is a modular, fiber-reinforced plastic grille. It is available in standard sizes or cut to customer-specified sizes. The horizontal and vertical cross structure design can effectively disperse the force, so the glass fiber grating designed in the square shape provides excellent force capacity. High density fiber materials provide maximum corrosion protection for many industries. Fiberglass grating is available in standard size designs of 1220× 3660mm.

Performance characteristics

- The integrated molding design structure improves the carrying capacity.

- The cross-designed bearing structure, dispersed the force, greatly improve the bearing capacity.

- Smooth and greasy surface is not easy to resist the adhesion of dirt.

- Excellent marine fiberglass grating has fine glass fiber and polyester resin cross which tightly interwoven together, providing excellent anti-corrosion ability.

- The hollow area reaches 70%.

Overall, marine bar grating is a versatile and reliable component of marine hardware, offering safety, durability, and functionality in demanding marine environments.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com