Marine Ball Valve

What Is a Marine Ball Valve

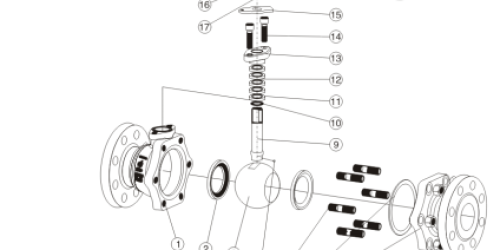

Marine ball valves consist of a ball with a round through hole for opening and closing. The ball valce moves with the stem to achieve opening and shut off. In order to open and close the channel, the opening and closing parts of the ball valve rotate around an axis perpendicular to the channel.

How Does a Ball Valve Work

Three-way marine valve can be flexibly cut off, distributed, and changed in flow direction in pipelines to cut off or adjust the use of the medium. Ball valves have a spherical sealing surface, therefore they are not easily washed by the medium, are easy to operate, and have a compact and simple design.

While the cock body rotates 90 degrees to lift, the difference is that it is a sphere with a circular channel passing through its axis. If the ball rotates 90 degrees, all the spherical surfaces should be present at the entry and exit, thus cutting off the flow.

The marine ball valve can be tightly closed with just a 90-degree rotation and a small amount of torque. As a result of the valve’s completely equal internal cavity, the medium flows smoothly and there is little resistance along the flow path. Traditionally, ball valves have been used for direct opening and closing, but recent developments have allowed them to be throttled and controlled.

Our Ball Valve Types for Sale

Floating ball valve

The flange connection floating ball valves produced by our factory is suitable for any pipes to be hoist. Its biggest advantages are small local resistance, quick hoisting, opening and closing of 90.It also has compact structure, good sealing performance and convenient maintenance. This kind of valve is widely used for water plant, electricity, chemical industry, foodstuff, paper making and medicine, etc.

- It has small local resistance and quick hoisting, which is easy to achieve quick hoisting.

- Channel in floating ball valve body is flat and smooth, which can transmit viscous fluid, slurry and solid particles.

- Kinds of driving mechanisms of manual, air-powered, electricity and hydraulic motive can be equipped, which can realize remote control.

Nominal pressure(MPa) | Nominal dimeter (mm) | Test pressure shell (Mpa) | Test pressure seal (Mpa) | Suitable temperature | Applicable medium |

1.6/2.5/4.0 | 15~200 | 2.4/3.75/6.0 | 1.76/2.75-4.4 | -20~150 | Fresh water, sewage, sea water. air, steam, food, medicine, acid, alkali, etc |

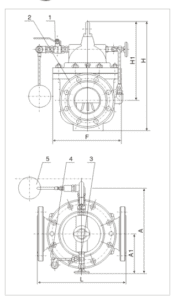

Remote-controlled float ball valve

The remote-controlled ball float valve generally has two types: diaphragm type and piston type, if the caliber of the floating ball valve is less than DN500mm, diaphragm type will be used, and it it is more than DN600mm, piston type will be used, and the action principles of the two kinds are similar.

The valve is composed of valve 2, needle valve 3, ball valve 1, as well as float valve5. Remote-controlled float valve can effectively control the water tank and the liquid level of the tower water pool, it timely turns off or opens the valve plug to let water flow or stops the water from flowing outside.

It can control the liguid level properly and prevent it from disturbing by the pressure surge, water can not leak due to its tightness and flexible float ball, it is also easy and convenient to maintain and tending. (Control of float ball and main valve can be installed separately), the remote controlled float valve can be widely applied in various automatic water supply systems such as industry and mining, enterprises, water tank in high buildings, water poll, as well as water tower, etc.

Nominal rating pressure 1.0 1.6 2.5 Nominal diameter 20~800 20~800 20~800 Test pressure shell 1.5 2.4 3.75 Test pressure seal 1.1 1.76 2.75 Flange ends standard GB/T17241.6-1998 GB/T17241.6-1998 GB9113.4-88 Applicable temperature(℃) 0~+80 Min pressure of motion P1>=0.07 Applicable medium Water

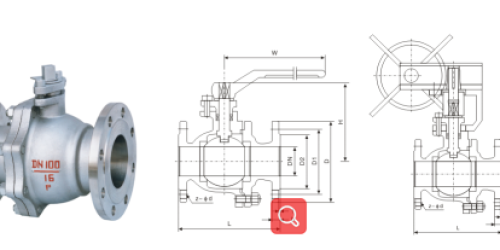

Flange-Fixed Ball Valve Series

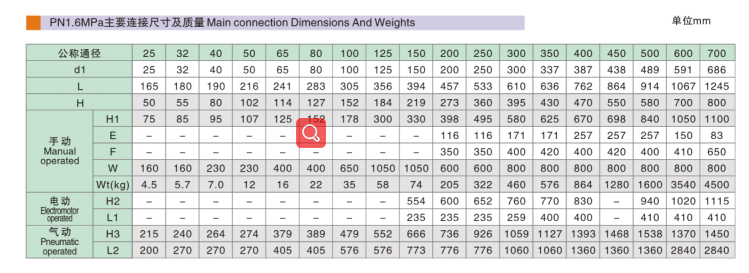

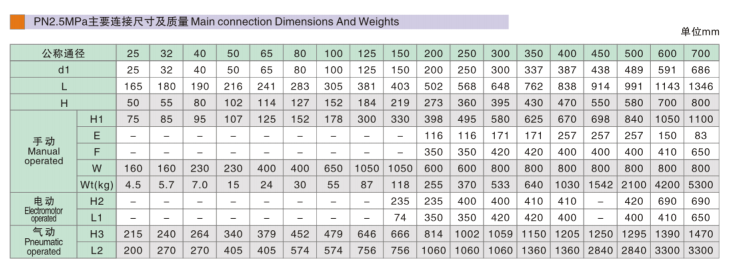

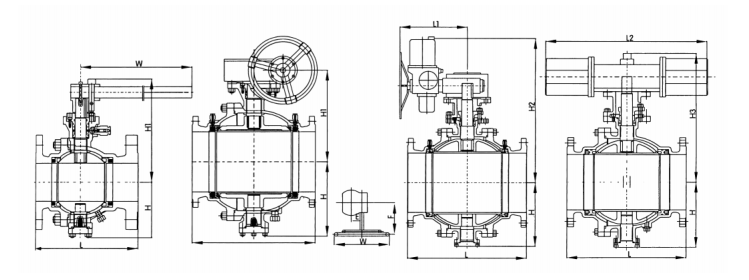

Flanged Ball Valve Specifications:

- Applicable medium: Water, gas, oil product, natural gas and corrosive mediums as acids, alkalis etc.

- Applicable Temperature: -196-350℃.

- Driving Means: Manual, pneumatic, motor, hydro-dynamic,etc.

- Inside Nominal Diameter: DN15-800mm 1/2″-32.

Design Reference | GB series | API series | |

Design Standard | GB/T12237 | AP16D | ANSI B16.34 |

Structural Length of Flange-Connection | GB/T12221 | AP16D | ANSI B16.10 |

Structural Length(Welding) | GB/T15188.1 | AP16D | ANSI B16.10 |

Connecting flange | GB/T9113 JB/T79 HG20592 | ANSI B16.5, B16.47 | |

Butt-weldin ends | GB/T12224 | ANSI B16.25 | |

Test & Inspection | GB/T9092 | API 6D | API 1598 |

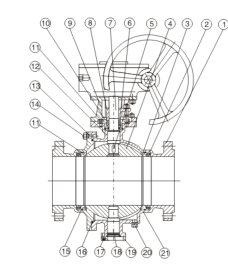

GB Fixed Ball Valve

- Design According to GB12237-89.

- Face to Face According to GB12221-89.

- End Flange Dimension According to JB79-94.

- Valve Check and Test According to GB13927-89

Threaded stainless steel ball valve

The stainless steel ball valve produced by Gosea Marrine has three kinds of structures: unitary, two-period form and three-l period form, which can be applied to various pipes as hoist. The biggest advantages of this product are its small fluid resistance, quick hoisting and 90° switch. It has compact structure and good sealing performance, it is also easy to maintain.

Marine ball valve Technical parameters:

- Connecting format: thread connection

- Nominal diameter: 1/2″-2″

- Nominal Pressure: 2.5/4.0/6.4MPa

- Applicable temperature range:-20-150℃

- Applicable medium: water, oil, gas and some corrosive liquid

- Thread type: G.NPT.BSPT.BSP

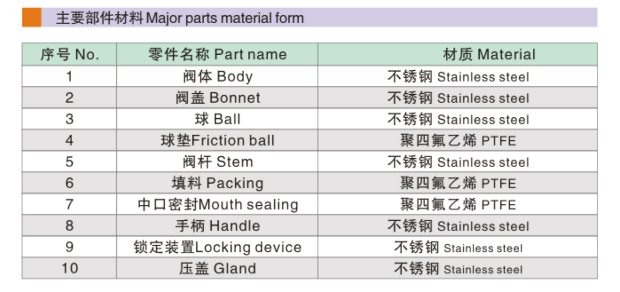

Features of Marine Grade Ball Valves

- Due to the alloy steel spray welding core and alloy steel surfacing sealing ring, the hard sealing stainless ball valve in the switch will not produce too much wear.

- Hard sealing ball valves have good sealing performance because spools and sealing rings need to be ground to match until they are completely matched.

- Therefore, it performs well in terms of sealing. Switches are very light when the external force exceeds the pre tightening force because the sealing ring and valve core are tightly held together by a spring on the bottom of the sealing ring of the hard sealing ball valve.

- In addition to its compact structure, easy operation and maintenance, the ball valve is suitable for general working media, such as water, solvents, acids, and natural gases, as well as harsh working media, such as oxygen, hydrogen peroxide, methane and ethylene. Integrated or combined marine ball valve bodies are available.

Diameter | DN15-DN800 |

Structure | Ball |

Medium | Water,Oil,Gas,Acid and alkali corrosion liquid |

Material | Carbon steel,Ductile iron,Bronze,Stainless steel |

Pressure | 1.0Mpa-50.0Mpa |

Temperature | -196℃–350℃ |

Connection | Thread,Flange,Welding,Butt welding |

Power | Manual,Pneumatic,Hydraulic,Electric |

Advantage of Our Marine Valves

- High precision, small deformation, good appearance quality, but also dense internal quality and good surface quality.

- By metallography structure, reducing porosity, shrinkage, and cracks, and other defects, the valve can be ensured of long service life.

- To ensure that the valve sealing face is processed accurately with Angle finish and matching sealing pair requirements, advanced production equipment is used.

- Gosea Marine have advanced assembly equipment and excellent personnel. The pressure seals on each product are tested before leaving the factory.

Types of Marine Ball Valves

Ball valve function classification:

- Bypass Ball Valve: ball valves are generally open for static water, so set up a bypass valve first flat pressure, that is, both sides filled with water.

- Air Ball Valve: when filling water, exclude the air to take the float to close the valve by itself; when draining, replenish the air with, the float falls by itself.

- Pressure Relief Ball Valve: open and close the valve, exclude the valve and the sealing cover between the pressure water, so as not to wear the sealing cover.

- Discharge Ball Valve: Discharge the sewage in the lower part of the ball shell.

Transmission classification:

- Pneumatic ball valve

- Electrical ball valve

- Pneumatic ball valve

- Pneumatic-hydraulic ball valve

- Electric ball valve

- Turbo drive ball valve

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com