Marine Container Lashing Equipment

Container Lashing Equipment and Fittings

Container lashing equipment refer to multiple products used for lashing. In the process of transporting containers, the system is combined in a particular way to solve the safety problem. The fastening system ensures the safety and reliability of transportation.

After years of development, the container fastening system has produced a variety of container fixed securing technologies, such as container technology for special lashing of containers , general-purpose container fastening technology for multi-purpose container lashing parts on ships that meet OSHA requirements Fastener technology. And many more.

With the different fastening technologies, there are many different types of binding and fastening products, including deck fixings, cabin fixings, deck movable parts, cabin movable parts, etc. Based on their application in special container ships or multipurpose containers, these products vary.

Our Types of Container Lashing Tools

- lashing for container binding fasteners are divided into binding parts and fasteners.

- Binding parts: including eye plate, flower basket screw, pull rod, etc.

- Lashing Containers Fasteners: including intermediate container twistlock, semi-automatic lock, bottom lock, midblock, etc.

Our company specializes in the development, design, calculation, production and sales of marine container lashing equipment, container fasteners, lashing parts and mooring equipment. The products include container fixing parts: embedded base, dovetail base, vertical base, perforated base plate, support seat, eye plate, D-ring and cleat, etc. Container Lashing Tools : container turnbuckles, lashing rods, bottom locks, center locks, semi-automatic locks, bridge yards, stacking cones, safety single cones and more than 60 varieties. At the same time, we have 20 feet and 40 feet flat rack, as well as various midsize frame boxes to meet the different needs of customers. Our products have complete certificates, we can provide CSS, UK LR, DNV, France BV, ABS, NK, KR and other ship inspection certificates.

Marine Fixed Securing Device

Fixed Securing equipment refers to the cargo securing points and their supporting structures welded to the interior of the hull structure (mainly referring to the cargo hold) and the exterior decks, hatch covers and struts.

The fixed securing device of this type of ship is directly welded to bulkheads, side ribs, struts and decks, and if necessary, directly welded to bilges and hatch covers. Its main types are:

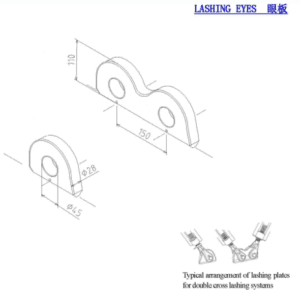

1.Lashing Equipment & Tool: Lashing Plate

The use of lashing eye plate location and role of the same D-Ring, mainly used for hatch cover, deck, container pillars and lashing bridge, multi-purpose ship will also be used for the bottom of the cabin, the main role is as a fastening point with the basket screws, lashing bars, etc. Composition of a fastening system to fix the container but generally not used in the cabin. There are single, double, three and four eyes and so on several kinds.

Lashing Eye Plate Specification:

- Weldable shop primer

- Min breaking loads tension: 500KN

- Other dimensions materials and finishes on request

- All items are approved by major classification societies

- Centre marking for easy installation

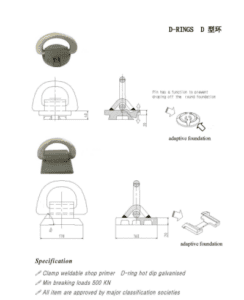

2. Container Lashing Equipment: D-Ring

D-Ring is mainly used for hatchcover, deck, container pillar and lashing bridge, multi-purpose ships also use it for bilge, the main role is as a fastening point and turnbuckle, lashing rods and other components of a fastening system to fix the container.

- Clamp weldable shop primer

- D-ring hot dip galvanized

- Min breaking loads: 500 KN

- Approved by major classification societies

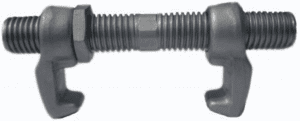

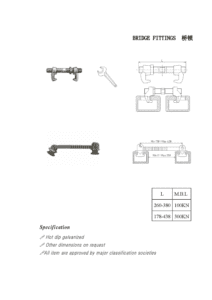

Shipping Container Bridge Fitting

Bridge fittings for shipping containers allow them to be connected horizontally. In the shipping industry, they are primarily used to ensure the safe transport of containers on board, but they are also widely used when two containers have to be securely joined horizontally. A shipping container bridge clamp can sustain a breaking load of 100 KN.

Specification:

- Hot dip galvanized

- Other dimensions on request

Container Corner Casting

The top hole of the Container Corner Casting is used for hoisting the spreader lock as well as the special frame for loading and unloading mechanical parts. It differs from the bottom hole. Bottom holes play a double-ended turning role between the upper and lower layers of the carrying box stack, as well as turning the ship. The lock box is mounted on the vehicle and the end hole is used for the lock box’s fixed operation. However, the side hole plays a relatively large role as well. Also, it can be used for the box’s bottom corners in addition to the above functions. Work involving lifting.

The top hole of the Container Corner Casting is used for hoisting the spreader lock as well as the special frame for loading and unloading mechanical parts. It differs from the bottom hole. Bottom holes play a double-ended turning role between the upper and lower layers of the carrying box stack, as well as turning the ship. The lock box is mounted on the vehicle and the end hole is used for the lock box’s fixed operation. However, the side hole plays a relatively large role as well. Also, it can be used for the box’s bottom corners in addition to the above functions. Work involving lifting.

It is difficult to carry out operations without corner fittings. All lifting, handling, fixing, and stacking of containers can be attributed to container corner casting, which provides the necessary conditions for container automation.

Marine Shackle Container Corner Casting

Marine Shackles are a kind of rigging. According to production standards, Marine Anchor Chain Shackles commonly used in the international market are categorized into national standard, American standard, and Japanese standard.

Among them, the American standard is widely used because of its size and weight.

Additionally, there are D-shaped shackles, Round Shackles, high-strength shackles, D-shaped locks, and C-shaped locks. Shackles can be dip-coated, spray-painted, electroplated and hot-dipped.

Marine Container Turnbuckle

Turnbuckles, also known as orchid screws, rigging buckles, and thread tightening buckles, are used to bind and fasten steel wire ropes. The turnbuckle is used to tighten steel wire rope and adjust the tightness. In general, OO type is used for infrequent disassembly, CC type for frequent disassembly, and CO type is used for infrequent disassembly on one end and infrequent disassembly on the other end.

Turnbuckles are composed of a rod, a nut, and a pull rod with left and right-hand threads.

An anti-theft and anti-loosening device is mounted on the adjusting rod, which is formed by connecting a cover plate, a fixing plate, and a guide plate with anti-theft and anti-loosening bolts. In order to unscrew the anti-theft locking bolt, you must use a special matching sleeve.

Shipping Container Twist Lock

By operating levers, shipping container twist locks are traditionally locked and unlocked manually. Lock the device and container on the hatch cover or other container by rotating the movable part around the vertical axis.

The twist lock has a left to right rotational lock. When the operating handle is in the firm position. The twist lock is in a non-locking state, and when the operating handle is rotated from right to left to the limit position, the twist lock rises to a locked state.

For this reason, the operating handle should first be placed in the non-locking state when in use. And place the corner hole or protruding foundation on the top of the container in the lower layer, and when the container in the upper layer is stacked neatly, rotate the operation handle to connect the container with the foundation.

When unloading the container, you should first use the twist lock lever to turn the operating handle to the twist lock unlocked position, and then unload the container.

Marine Container Foundation

The primary function of the Marine Container Foundation is to provide a stable platform for containers, preventing movement, shifting, or toppling during rough seas or vessel maneuvers. This is achieved through a combination of secure fastening methods, such as twist locks, corner castings, and other lashing mechanisms, which hold the containers firmly in place. The foundation ensures that the containers remain securely connected to the ship’s structure, minimizing the risk of cargo damage, loss, or accidents.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com