What is A Sacrificial Anode

Sacrificial anode, is a type of marine anode specifically designed for use in marine environments, which is to protect the ship’s metallic components from corrosion.

Ships are exposed to highly corrosive conditions due to the presence of saltwater and other electrolytes. To prevent corrosion and extend the lifespan of the ship’s hull, propellers, rudders, and other submerged metal parts, sacrificial anodes are strategically installed. These boat anodes are typically made of materials like zinc or aluminum, which are more electrically active than the ship’s metal components. As a result, the sacrificial anode corrodes over time while the protected ship components remain relatively unaffected.

The Types of Marine Anodes

Marine sacrificial anodes are divided into five types according to their material composition, including aluminum-zinc-indium-cadmium alloy anodes, aluminum-zinc-indium-tin alloy anodes, aluminum-zinc-indium-silicon alloy anodes, aluminum-zinc-indium-cadmium-magnesium alloy anodes, aluminum-zinc-indium-magnesium alloy anodes.

Sacrificial anodes for hull cathodic protection are divided into three types, including single-iron foot welded, double-iron foot welded and bolt-connected marine anodes.

Our Boat Zinc Anodes Chemical Composition

Gosea marine is one of the zinc anode manufacturers, If there are special specifications, Our factory can cast production according to drawings and samples.

Sacrificial Anode Types | Zn | In | Cd | Sn | Mg | Si | Ti | impurity content | Al |

Al-Zn-In-Cd(A11) | 2.5~4.5 | 0.018~0.050 | 0.005~0.020 | – | – | – | – | 0.26 | Remain |

Al-Zn-In-Sn | 2.2~5.2 | 0.020~0.045 | – | 0.018~0.035 | – | – | – | 0.26 | Remain |

Al-Zn-In-Si | 5.5~7.0 | 0.025~0.035 | – | – | – | 0.1~0.15 | – | 0.26 | Remain |

Al-Zn-In-Si-Mg | 2.5~4.0 | 0.020~0.050 | – | 0.025~0.075 | 0.50~1.00 | – | – | 0.26 | Remain |

Al-Zn-In-Mg-Ti | 4.0~7.0 | 0.020~0.050 | – | – | 0.50~1.50 | – | 0.01~0.08 | 0.26 | Remain |

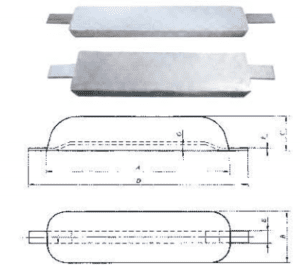

Weld-on Marine Anode

The weld-on sacrificial anode is typically made of materials such as zinc anodes for boat, aluminum anodes, or magnesium anodes, which are more electrically active than the ship’s hull. This means that the boat anode will corrode preferentially, diverting the corrosion away from the ship’s hull and other metal components

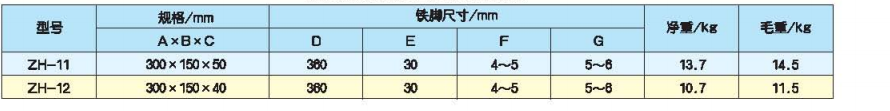

Weld-on Sacrificial Anode Size

Model | Size/mm | Net weight(kg) | Gross weight(kg) |

ZH-1 | 800*140*60 | 45.4 | 47.0 |

ZH-2 | 800*140*50 | 37.4 | 39.0 |

ZH-3 | 800*140*40 | 29.5 | 31.0 |

ZH-4 | 800*120*50 | 24.0 | 25.0 |

ZH-5 | 400*120*50 | 15.3 | 16.0 |

ZH-6 | 500*100*40 | 12.7 | 13.6 |

ZH-7 | 400*100*40 | 10.6 | 11.0 |

ZH-8 | 300*100*40 | 7.2 | 7.5 |

ZH-9 | 250*100*40 | 6.2 | 6.5 |

ZH-10 | 180*70*40 | 3.3 | 3.5 |

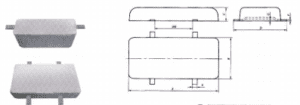

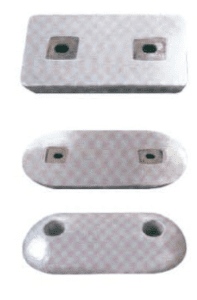

Bolt-on Marine Anodes

The “bolt-on” aspect refers to the method of attachment. These Bolt-on anodes are designed with pre-drilled holes or threaded inserts, allowing them to be easily bolted or fastened onto the ship’s hull or other metal surfaces using appropriate hardware. This ensures a secure and reliable connection that withstands the harsh marine environment.

Bolt-on Sacrificial Anodes Size

Model | Size/mm | Net weight(kg) | Gross weight(kg) |

ZH-13 | 300*150*50 | 11.6 | 12.0 |

ZH-24 | 300*150*40 | 8.6 | 9.0 |

Bracelet Sacrificial Anode

The bracelet anode is generally wrapped around the structure to be protected, such as a boat hull or a submerged metal pipe. It is secured in place using clamps, bolts, or other fastening mechanisms. The anode should have good contact with the protected structure to ensure effective corrosion protection. It is typically made from highly active metals such as zinc, aluminum, or magnesium. These metals have a higher electrochemical potential than the protected structure, which ensures that they corrode sacrificially.

Bracelet Anode Specification

Size(mm) | Dimension of steel core | Gross weight(kg) | ||

E | F | G | ||

420×622×51×20 | 480 | 4 | 6 | 270.4 |

254×559×76×25 | 284 | 4 | 6 | 210.6 |

400×503×51×25 | 430 | 4 | 6 | 210.0 |

562×371×51×25 | 592 | 4 | 6 | 210.0 |

Marine Sacrificial Anode Installation Method

- The marine anode block in the hull outer underwater parts placed number, should be based on the performance of ship structure, navigation area and materials as anode, calculation formula determined, in general can be repaired in reference to the original number, area or the calculation of the corresponding replacement. Not found inadequate should be appropriately increased, if have protection should be reduced accordingly.

- The sacrificial anode installation location should be uniform configuration and try to reduce the flow resistance, the whole ship anode block with 1/3-1/2 concentration in the tail, the installation angle should be consistent with the flow direction, should avoid in an anode with the anode anode arrangement can refer to put, external hull diagram.

- The installation of marine anode block, is generally used welding method, but also allows the installation of the screw fixation. The welding method when the anode block back pressure hull after the iron feet firmly welded hull body, and knock on the net welding slag. Bolt fixing method is used in the aluminum shell heat exchanger for ship, countersunk screw fastening screw head should be put in the upper lacquer ash or cement, to prevent loosening of screw hole corrosion. The anode in the installation of the back is coated with a layer of insulating paint.

- The boat anode block fixed screw loose, re installation or replacement shall be.

- The ship anode block surface is painted or stained, iron foot joints shall be painted after welding.

- The anode service life: generally 1 to 3 vears, but our factory can also be based on customer requirements, to provide anode design, more than 3 years machining.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com