Marine Check Valve

Ship Check Valve for Sale

Marine check valves are circular discs with opening and closing parts that prevent medium backflow by their own weight and medium pressure action. There are two types of disc movements: lifting and swinging. Unlike globe valves, lift check valves do not have a stem to drive the disc. Flow of the medium occurs from the inlet end (lower side) to the outlet end (upper side). When the inlet pressure exceeds the sum of the disc weight and the flow resistance, the valve opens. In the event that the medium flows backwards, the valve is closed. As with lift check valves, swing check valves have an oblique disc that rotates around the shaft.

Purpose of Check Valve

Gravity check valves with flanges are the most commonly used type. When the working medium with a certain pressure enters the inlet valve cavity of the check valve, the force of the working medium acts on the underside of the valve disc to overcome gravity, causing the valve disc to rise along the guide groove on the cover and leave the valve. At this point, the channel of the check valve is opened.

By gravity, the valve disc falls back to the valve seat when the working medium returns to the inlet chamber of marine check valve. During this time, the returning working medium acts on the valve disc. By pressing the disc tightly against the valve seat, the check valve closes, preventing backflow.

Swing arm check valves are also available in addition to gravity check valves. It is also called the anti-wave valve. An anti-wave valve consists of a valve body, a valve disc, and a rotating shaft. The working medium is contained in the valve cavity, which is an advantage. Gravity check valves have a lower flow resistance.

There is also a flange and thread type connection between the check valve and pipeline. Cast iron, cast steel, and bronze are the metal materials used to make check valves (mainly the valve body).

Marine Check Valve Types

Wafer butterfly check valve

The wafer butterfly check valve of our factory adapts foreign advanced structure design, which meets the relevant national standards, so it belongs to energy-efficiency type production. This production has good check performance and small local resistance coefficient, which is also safe and reliable; it is mainly used as one-way valve in the systems of petroleum, chemical industry, foodstuff, medicine, lighttextile, papermaking, water supply and drainage, smelting, as well as energy, etc.

Product features

- It has small volume, light weight, compact structure and convenient maintenance.

- The valve board takes antithetic formula, which can achieve quick-closing automatically under the flexibility torque of spring.

- The medium can be prevented to backflow because of quick-closing, and the fire-fighting water hammer has strong function.

- The length of valve body structure is small, and it has good rigid, which is also safe and reliableIt achieves complete sealing, and the leakage of hydrostatic test is zero.

- It is convenient to install, which can be installed in horizontal direction and vertical direction.

- The connection size of flange meets the standard of GB/T 17241.6-98.

- The structure length meets the standards of GB/T12221-89 and ISO5752-82.

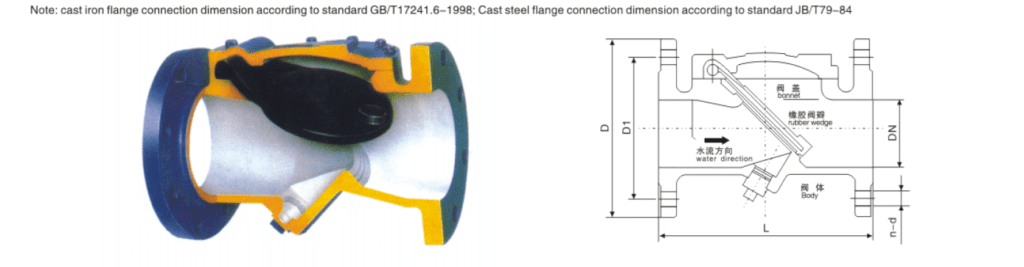

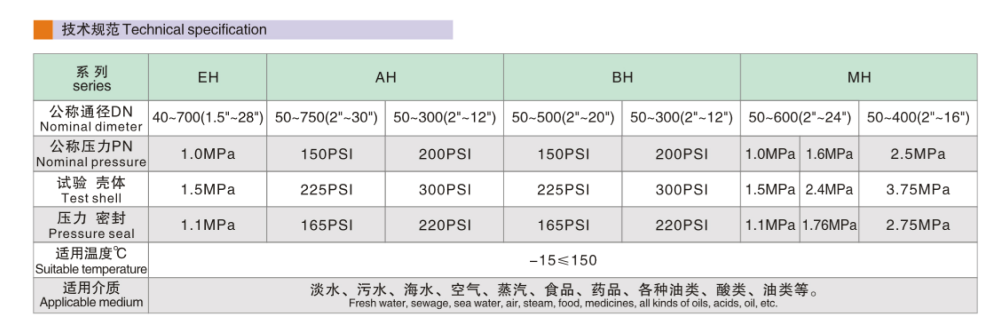

Rubber Disc Check Valves

This valve is mainly used at pipe pump exit in the industrial sectors of drainage system, petroleum and chemical industry, etc, in order to prevent medium backflow. Because the seal ring of this production takes an oblique design, there is a short closing time, so as to reduce the pressure of the water hammer. The valve clack takes the combination of nitrile rubber with steel plate pressed by high temperature, which has a strong ability to resist washing and good sealing performance; this production also has a simple structure and at the same time it is convenient to maintain, service and transport.

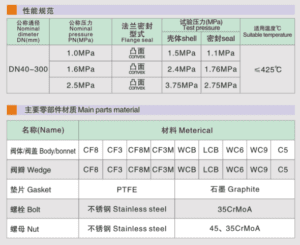

Nominal pressure PN (MPa) | Nominal dimeter DN(mm) | Shell Test pressure (MPa) | Seal Test pressure (MPa) | Applicable medium |

1.0 | <80 | 1.5 | 1.1 | Clear water and oil |

1.6 | <80 | 2.4 | 1.76 | Clear water and oil |

2.5 | <80 | 3.75 | 2.75 | Clear water and oil |

GB swing check valve

This swing check valve is suitable for various operation modes of petroleum, chemical industry, pharmacy, fertilizer and electric power with nominal pressure of PN1.6-2.5MPa. The working temperature of -29-550℃, and the suitable mediums are water, oils, steam and acidic medium, etc.

Hydraulic Control Check Valve for Sale

300X Slow Closing Check Valve

Our 300X slow closing check valve is a type of valve that is designed to prevent the backflow of fluid in a piping system. It is called “300X” because it has a closing time of 300 times slower than a standard check valve. The valve combines the functions of an electric valve, a check valve, and a water hammer eliminator, helping to minimize water hammer effects to the maximum extent possible.

- The non-return valve which can adjust the speed of open and close.

- During the open and close of the water pump working, adjust the best speed of starting system.

- Protect water pump by effectively reducing the phenomenon of water hammer and water attack.

Function of A Check Valve

A marine check valve should be provided when reverse flow of fluid is not allowed in the pipeline. The inline check valve do not have stems. As the pressure on one side of the valve increases, the valve can be pressed against the seat; as the fluid acts on the other side, the valve can be opened. A lift type water check valve and a swing type check valve are the two most common types of marine valves.

Diameter | DN40-DN600 |

Medium | Water, Oil, Gas, Acid and Alkali Corrosion Liquid |

Material | Carbon Steel, Ductile Iron, Bronze, Stainless Steel |

Pressure | PN1.6-16.0MPa |

Temperature | -29℃-550℃ |

Connection | Thread, Flange, Welding, Butt Welding |

Power | Manual, Pneumatic, Hydraulic, Electric |

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com