Marine Globe Valve

What Is A Globe Valve

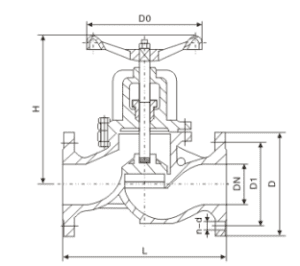

The Marine globe valves, also known as the shut off valve, belong to the forced sealing valve, so when the valve is closed, pressure must be applied to the valve disc to force the sealing surface not to leak. When the medium enters the valve from the bottom of the disc, the resistance that the operating force needs to overcome is the friction force of the stem and the packing and the thrust produced by the pressure of the medium. The force of closing the valve is larger than the force of opening the valve, so the diameter of the stem is larger, otherwise, the failure of the stem top bend will occur.

Marine globe valves have significant results in the corrosion resistance of seawater. It is slightly different from the stop valve of general material. There are mainly stainless steel globe valve and brass globe valves.

Diameter | DN10-DN300 |

Medium | Water, Oil, Gas, Acid and Alkali Corrosion Liquid |

Material | Carbon Steel, Ductile Iron, Bronze, Stainless Steel |

Pressure | PN1.6-PN4.0 |

Temperature | ≤425 |

Connection | Thread, Flange, Welding, Butt Welding |

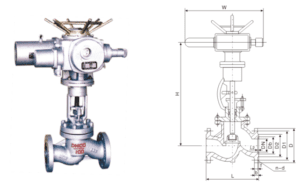

Power | Manual, Pneumatic, Hydraulic, Electric |

Application of Marine Stop Valve

Marine stop valve opening and closing parts are plug-shaped disc, sealing surface is flat or conical surface, the disc is along the centerline of the seat for linear movement. Because the valve stem open or close stroke is relatively short, and has a very reliable cutting function, and because the valve seat vent changes and the stroke of the valve disc into a directly proportional relationship, very suitable for the flow of the regulation.

Globe Valve Types

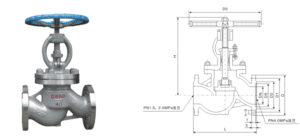

Flange connection steel stop valve

The flanged globe valve is suitable for various operation mode pipes of petroleum, chemical industry, pharmacy, fertilizer and electric power with nominal pressure of PN1.6-4. OMPa. The working temperature of-29-425℃, which can cut off or get through the pipe medium. The suitable mediums are water, oils, steam and acidic medium, etc. Its operation modes are manual operation, gear transmission, power-driven and air-powered.

The flanged globe valve is suitable for various operation mode pipes of petroleum, chemical industry, pharmacy, fertilizer and electric power with nominal pressure of PN1.6-4. OMPa. The working temperature of-29-425℃, which can cut off or get through the pipe medium. The suitable mediums are water, oils, steam and acidic medium, etc. Its operation modes are manual operation, gear transmission, power-driven and air-powered.

It can take various standards of piping flange and flange sealing surface modes, in order to satisty various engineers’ requirements and users’ demand.

Flange connection cast iron stop valve

- This cast iron flanged globe valve is suitable for pipes and equipments of liquid and gas mediums. It can be used as medium in pipes of getting through and cutting off.

- It has good sealing performance and easy operation, and the sealing surface is not easy to bedamaged, it also has long service life, and it is difficult to produce water hammer, etc.

- It can be installed at any position of pipe, but the flow direction should be installed according to direction. Clockwise of hand wheel means closing, on the contrary it means opening. and it is forbidden to use anv prv.

- The design and manufacture meet the standards GB/T12237-1989.

Nominal pressure(Mpa) | 1.6 |

Suitable temperature | <200 |

Applicable medium | Water, oil, gas and non corrosive mediums |

Main Material | Gray cast iron, brass, chrome-plated carbon steel, Tefion |

Features of Marine Cut-off Valve

- This production has a reasonable structure, reliable sealing, excellent performance, and a beautiful appearance.

- The valve clack and sealing surface of the valve seat are made by resurfacing welding of iron-based alloy or Satellite cobalt-based alloy, which is wear-resistant, high temperature resistant, and corrosion resistant, it also has a long service life.

- The valve stem is treated by quenching and tempering, as well as surface permeability ammonia, so it has good corrosion resistance and abrasion resistance.

- It can take various standards of piping flange and flange sealing surface modes, in order to satisfy various engineers’ requirements and users’ demands.

- The valve body materials have complete varieties, which can be fitted reasonably according to actual operation mode and user’s requirement, it is also suitable for various pressures, temperatures, and medium operation modes.

- It has reliable sealing, and replacing fling can be operated without stopping the machine, so it is convenient and quick, which won’t affect system running.

Precautions About Marine Shut-off Valves

The following two points should be paid attention to when selecting and installing the globe control valve.

1. According to different working media and working conditions, select the appropriate material and connection method of the stop valve (different working conditions include the pressure, temperature and flow of the working medium);

2. The installation of the shut-off valve must strictly abide by the principle of low inlet and high outlet, and pay attention to the mark of the flow direction on the valve body.

To close or open the general shut-off valve, just turn the handwheel directly. Some marine shut-off valves are equipped with a gear drive opening device. The biggest advantage of using this drive device to open or close the valve is that it can reduce the labor intensity of the operator. At present, this kind of valve is only used in underwater seawater systems.

Note: The ballast water pipe passing through the collision bulkhead should be equipped with a shut-off valve capable of operating above the freeboard deck (the bulkhead deck of a passenger ship). The valve should be installed on the fore-point tank side of the fore-point bulkhead It also has a device to indicate whether the valve is open or closed, so that the valve can be closed on the deck immediately in the event of head sea damage to prevent seawater from entering the ballast water system.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com