Marine Windlass

About Marine Anchor Windlass System

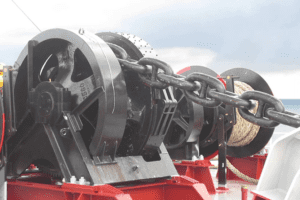

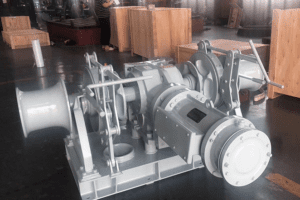

Marine windlasses come with a motor, anchor chain wheel, winch drum, an anchor chain wheel, and a support. With the winch drum mounted on the support, the motor is connected to the anchor sprocket and the winch drum’s main shaft through the gear transmission chain, a standby drum is mounted at the rear of the support, the standby drum and the winch drum are disposed concentrically, and a clutch is attached between the standby drum and the winch drum.

Utility model windlass anchors are also equipped with a standby drum, which improves not only the vessel’s ability to rescue and construct, but also its safety performance.

What is A Windlass Anchor

Windlasses for marine anchors are primarily intended to stabilize the position of a ship while anchoring. It controls the ship’s speed and rotation during mooring maneuvers. Contains a prime mover, a reducer, a clutch, a winch, a chain disk, brakes, and control devices.

While both the marine windlass and winch involve the winding and unwinding of cables or ropes, their specific functions and applications differ. The windlass is dedicated to anchoring operations, while the marine winch is a more versatile device used for a range of pulling and lifting tasks on a boat or ship.

Types of Anchor Windlass for Sale

There are seven types: Electric Windlass, Hydraulic Windlass, Diesel engine driven windlass, Manual anchor Windlass, Combination Windlass, Vertical Windlass, Horizontal Windlass.

Vertical Windlass On Ship:

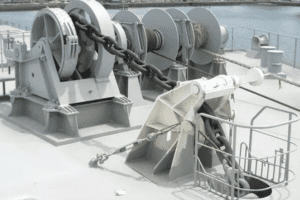

Since their power part is under the deck, they take up little deck space. Vertical windlasses are usually found on warships. Because large ships have relatively large windlasses, the bow deck is unfavorable for the operation, so vertical windlasses are often used instead.

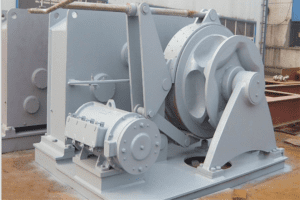

Horizontal Windlass On Ship:

Horizontal windlasses have a horizontally oriented drum or gypsy. They are often larger in size and suitable for boats with more deck space. Horizontal windlasses can handle chain and rope rode and provide excellent control during anchor handling.

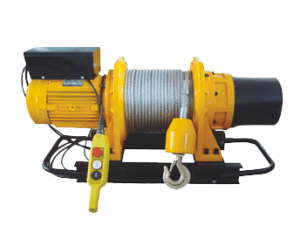

Electric Windlass for Boat

Electric Anchor Windlass are popular due to their convenience and ease of use. They are powered by an electric motor, typically connected to the vessel’s battery or electrical system. Electric windlasses offer controlled and efficient deployment and retrieval of the anchor, often with the ability to operate remotely from the helm.

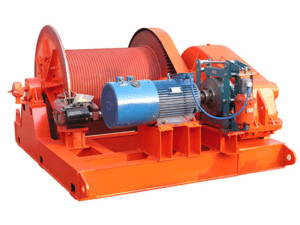

Hydraulic Anchor Windlass:

Hydraulic windlasses are powered by marine hydraulic systems, utilizing pressurized fluid to drive the windlass. They are known for their high power and reliability, making them suitable for larger vessels. Hydraulic windlasses provide strong pulling force and smooth operation.

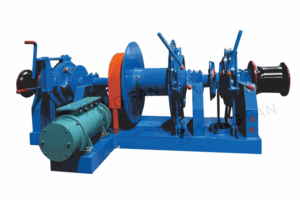

Diesel Engine Driven Windlass

A diesel engine-driven windlass refers to an anchor windlass system that is powered by a diesel engine. It is commonly found on larger vessels, such as commercial ships, ocean-going vessels, or larger yachts.

These windlass systems typically consist of a diesel engine, a transmission or gearbox to transfer power to the windlass mechanism, and a drum or gypsy to handle the anchor chain or rope. The operator can control the windlass operation from a control panel or station, allowing for precise handling and control during anchoring operations.

Manual Anchor Windlass On Ship

Manual windlasses require physical effort from the user to operate. They are usually equipped with a hand crank or handle that is turned to raise or lower the anchor. Manual windlasses are simple, reliable, and commonly found on smaller boats or as backup systems on larger vessels.

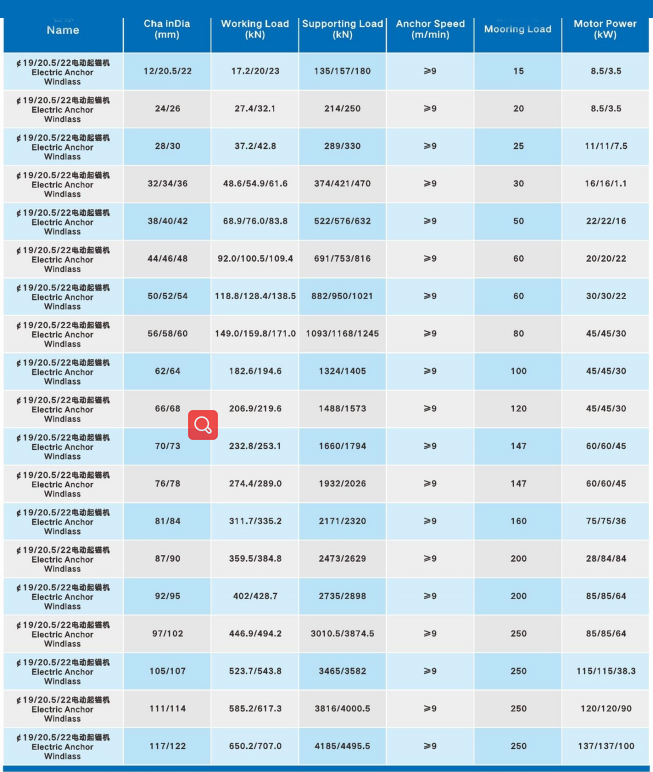

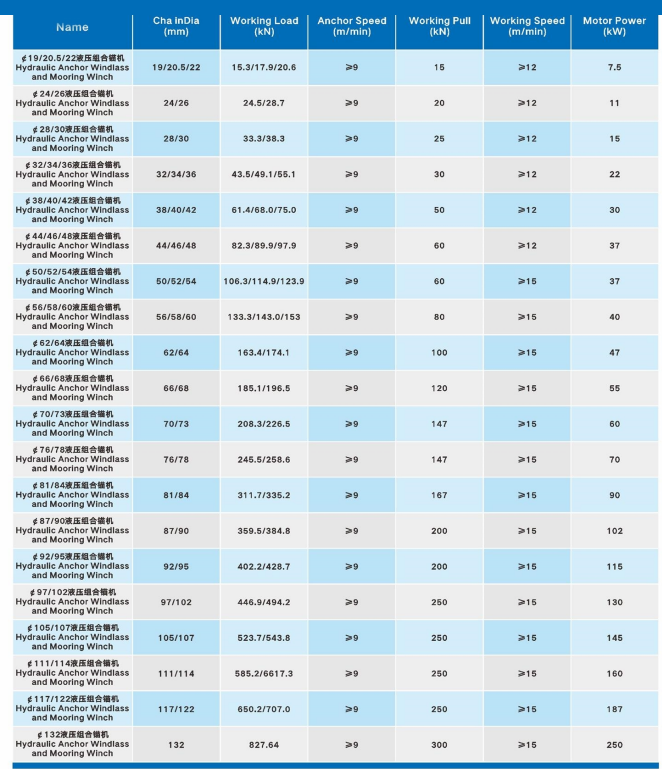

Anchor Windlass Parameter Table

Gosea Marine's Windlass Feature

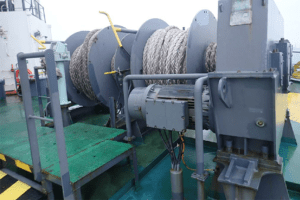

- Drum transmission structure: two-stage gear reduction transmission mode is used.

- Directly driving the drum is the coupling. Wire ropes can easily be replaced or rotated in a different direction by changing their direction of rotation.

- Wire rope fixation: install a Pt screw on the drum, which is safer than ordinary wire rope fixation. It prevents the steel wire rope from escaping.

- Electromagnetic braking is used for braking. Choose brake pads that are wear-resistant. It is simple and does not require clearance adjustment. The brake will start automatically when the power is turned off. It can control the drop distance for heavy loads, which is safe and reliable.

- Gearbox: made of nodular cast iron fcd-45# steel. Durable and rigid.

- Special motor: insulation type B, large starting torque, small inertia, low-temperature rise, and can work frequently for a long time.

- High-quality steel is used for the transmission device. Precision machining and heat treatment are required. Among its characteristics are wear resistance, low noise, high driving efficiency, and good performance.

- Machine fixture: standard channel steel welding. Used in construction sites, warehouses, ports, etc.

Windlass supporting products

Marine windlasses and anchoring gear are also called anchoring gear. Refers to the ship’s marine chain stopper, anchor chain, windlass, anchor and ancillary equipment.

Marine Chain Stopper

Anchor chain stoppers are designed to prevent anchor chains from directly pulling on the windlass by quickly securing the chain.

Anchor chains are clamped by chain stoppers to prevent them from slipping when the ship sails or anchors. They are also called anchor chain stoppers or chain stoppers. The chain stopper must withstand a load equivalent to the anchor chain, and its stress should not exceed 90% of its yield strength. Under these conditions, the chain stopper should be able to withstand 80% of the minimum breaking load of the chain that passes through it.

It is attached between the windlass and chain cylinder and separate from the chain wheel. As the anchor is retracted and anchored, the anchor chain and anchor pull force will not be transmitted to the anchor sprocket wheel. Chain stoppers include spiral, lever, tongue type, devil’s claw, and roller knife chain stoppers.

Our Marine Anchor Chain

Marine anchor chains connect the anchor to the hull, and are used to transfer and buffer external forces. Anchor chains may also cause friction.

Chains can be classified into two types based on the type of link they have: gear chains and non-gear chains. When the chain size and material are the same, the chain with a chain has greater strength, deformation is small, and it does not twist when stacked, so it is widely used on seagoing ships. Chains without gears are generally found on small boats.

Based on the manufacturing method, anchor chains can be divided into cast steel anchor chains, electric welded, and forged anchor chains. Three steel grades are used in the production of geared anchor chains: AM1, AM2, and AM3. AM1 anchor chain steel is killed steel, AM2 is killed fine-grained steel. The chain link size can be reduced appropriately if strong steel is chosen for the same ship.

Recommended: Our Marine Anchor

According to the specification of fitting-out of selection, a ship must carry the number and weight of anchors. It can also be determined by the ship’s displacement, the water windage area, the appendage resistance, the anchoring depth, and the chain length. Anchors, in a small anchor, do not make specific provisions. Ships generally have three main anchors (two box anchors and one spare anchor). As a result of the small superstructure of the boat, submarine anchors are short-handled so as to avoid layout difficulties. An anchor must be able to reach the maximum holding power under the rated weight and must be able to quickly engage in various subsoil conditions under any drop condition. When the anchor is lifted, it is easy to escape the soil. Anchor chains, anchor holes or anchor frames work well with it.

The bow anchors commonly used on merchant ships are all rodless anchors, while stern anchors are sometimes used with rod anchors or dovetail anchors.

Instant Quote Online

Dear friend, Thank you for reaching out to us. We understand the urgency of your needs, and we’re here to assist you. You can conveniently submit your pressing requirements online, and our dedicated staff will promptly get in touch with you to provide the assistance you require.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com