Marine Centrifugal Pump

What is Centrifugal Pump?

Marine centrifugal pumps are often needed to transport water, oil, and other liquids in ship power systems and ship systems. The working principle of a centrifugal pump application is to convert the mechanical energy of high-speed rotation of a motor into kinetic energy and potential energy of the promoted liquid, which is a process of energy transfer and transformation.

Our Ship Centrifugal Pump for Sale

Vertical self-priming centrifugal pump

Our CWZ Series marine vertical self-priming centrifugal pump offers a range of benefits, including its compact structure, attractive appearance, and epexcellent self-priming performance. Self–priming centrifugal pump is designed to accommodate different media types by utilizing various materials, making it suitable for transporting ship bilge and ballast water, as well as for cooling sea water, fire suppression, and sanitation purposes. The pump is specifically intended for use with seawater or freshwater, with a maximum transportation temperature of 85℃.

Marine Multistage Stainless Steel Centrifugal Pump

The TPY Series vertical multistage stainless steel marine industrial centrifugal pump is a stainless steel pump known for its exceptional performance. It is designed to handle a wide range of liquids, including water, soft water, swimming pool water, and slightly alkaline solutions, without significant corrosion. With its stainless steel construction (304 or 316L), the pump ensures durability and reliable operation. It is widely used in various applications, such as liquid transportation, circulation and pressurization of hot and cold clean water, softened water, mineral water, and distilled water. The TPY Series pump offers numerous advantages, including low noise, corrosion resistance, an attractive appearance, compact size, smooth operation, easy installation, and a long service life. It is ideal for applications where high-quality performance and longevity are essential.

How Does a Marine Centrifugal Pump Work?

When the marine industrial centrifugal pump works, the impeller rotates at a high speed. The liquid in the impellers for pumps is pushed by the blade and rotates with the centrifugal impeller. Under the action of centrifugal force, the liquid is thrown out from the center of the centrifugal impeller. Then the pump shell flow channel with a gradually expanding section is collected, and most of the kinetic energy is converted into pressure energy through the diffuser, which is discharged from the discharge pipe.

At the same time, a certain vacuum is formed in the center of the impeller. The liquid is sucked into the centrifugal pump impeller through the suction pipe under the effect of pressure difference. Therefore, as long as the impeller can maintain uniform rotation. The marine centrifugal pump insight can continuously inhale and discharge liquid, maintaining the normal operation of the pump.

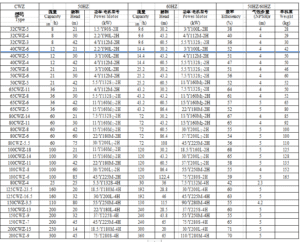

Gosea Marine’s centrifugal pump for sale, the flow rate can be from 0.5 m3/h to 2000 m3/h, and the head can be from 3 ms to 200 ms.

Features of Marine Centrifugal Pump

1.The base of the centrifugal pump application generally forms a common base together with the motor, which is mostly made of cast iron. The base is equipped with a bearing seat for installing bearings to support the pump shaft. Both ends of the bearing seat are equipped with bearing covers and installed on the base with bolts. An oil filling hole is arranged on the bearing seat or cover for filling grease to the bearing. Note: do not add lubricating oil.

2.The pump casing (volute) is mostly made of cast iron and fixed on the base with bolts. The centrifigual pump casing is equipped with a diffuser and shaft seal box, and the top is equipped with a vent valve. It is used to vent air when filling the pump, and a water drain cock is set at the bottom to vent water when the pump is stopped when the temperature is lower than zero to prevent freezing crack of the pump.

3.The shaft seal box is equipped with a water seal ring and packing inside and packing gland outside, which is used to compress the packing and seal the pump shell.

4.The pump shaft is supported by a bearing and installed on the base. One end is equipped with an centrifugal pump impeller and the other end is equipped with a coupling. It is driven by the prime mover to drive the impeller to rotate.

5.The impeller, made of bronze, brass, or cast iron, is installed on the pump shaft, located in the pump housing, and the outer end is fixed by the impeller fixing device. Impeller fixing nuts are mostly left-hand threads to prevent repeated starting and loosening due to inertia.

6.The Marine Seal ring is made of copper alloy or phenolic resin. It is divided into a moving ring and a static ring. The moving ring is installed on the impeller and the static ring is installed on the pump shell for sealing between the pump shell and the suction inlet.

Diameter | DN15-DN800 |

Structure | Ball |

Medium | Water,Oil,Gas,Acid and alkali corrosion liquid |

Material | Carbon steel,Ductile iron,Bronze,Stainless steel |

Pressure | 1.0Mpa-50.0Mpa |

Temperature | -196℃–350℃ |

Connection | Thread,Flange,Welding,Butt welding |

Power | Manual,Pneumatic,Hydraulic,Electric |

Structure of Marine Centrifugal Pump Insight

- Castingblank high precision, small deformation, good appearance quality, but also to have dense internal quality and good

- metallographystructure, reduce the porosity, shrinkage, cracks and other defects can ensure the service life of the

- Advancedproduction equipment, to ensure that the valve sealing face in the processing accuracy with Angle finish and matching sealing pair

- Theassembly equipment is advanced and the personnel is Before leaving the factory, each product is tested for the performance and quality of the pressure seal.

Types of Marine Centrifugal Pump

- PFstrong corrosion-resistant centrifugal pump is an energy-saving centrifugal pump developed for strong corrosive media without Pf strong corrosion-resistant marine centrifugal pump for sale has the advantages of high mechanical strength, good corrosion resistance, energy-saving, and environmental protection, wide application, convenient maintenance, and can transport a variety of strong acids.

- CISseries marine horizontal centrifugal pump is a high-efficiency and energy-saving product designed according to the unique structural combination of CIS centrifugal pump and vertical The horizontal centrifugal pump application is optimized by a domestic advanced hydraulic model. The horizontal centrifugal pump also derives hot water marine industrial centrifugal pump, high-temperature centrifugal pump applications, chemical centrifugal pump for sale, and oil pump based on CIS centrifugal pump for sale according to different service temperature and medium. It is a finalized and promoted product of national standards at present.

- AYsingle-stage and two-stage centrifugal pump series are reformed and redesigned on tee basis of the old Y-type centrifugal oil pump The marine centrifugal pump is a new product developed to meet the needs of modernization and adapt to the renewal of energy-saving equipment as soon as possible.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com