Marine Gangway

Our Marine Gangway and pilot ladder are produced by professional factories. They are personnel boarding equipment. Most of them are made of aluminum alloy. After passing the inspection, the marine product inspection certificate will be issued by the classification society. The shipyard only conducts installation inspection and various tests after installation.

1. It is usually stored on the ship’s side, and when it is used, it is released outboard and inclined along the side of the ship for personnel to get on and off the ship.

2. Ladders suspended overboard for boarding and disembarking of the ship, which can be lifted, turned over and stored in the side of the ship.

3. A set of movable steps located on the side of the boat for personnel to use when boarding from the boat or the dock.

Our Ship Gangway for Sale

Dock Gangway

A dock gangway is a versatile and movable bridge or ramp that facilitates safe and seamless transitions between a dock or pier and a land-based structure. It serves as a vital link, allowing easy access for individuals and equipment from the dock to the adjacent land area. Dock gangways are designed to ensure safety and convenience during embarkation and disembarkation processes, providing a sturdy and reliable pathway for smooth passage between the water and land. They come in various sizes, materials, and configurations to accommodate different dock layouts and water levels. Whether for commercial ports, marinas, or recreational docks, dock gangways play a crucial role in enabling efficient and secure movement between watercraft and land facilities.

Aluminum Dock Gangway for Sale

- Standard: IS07081-2004

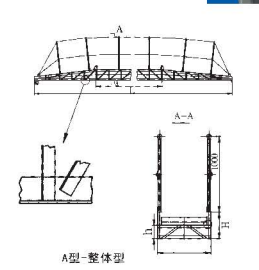

Type A: Integral type

Tpye | L | I | H | h |

A8 | 8000 | 3200 | 350 | 180 |

A10 | 10000 | 4630 | 500 | 250 |

A12.5 | 12500 | 4830 | 550 | 300 |

A15 | 15000 | 7230 | 750 | 500 |

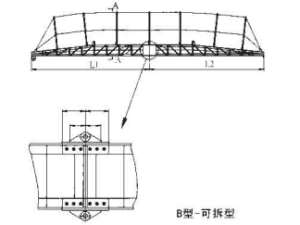

Type B: Detachable type

Type | L1 | L2 | H | h |

B8 | 4000 | 4000 | 350 | 180 |

B10 | 6000 | 6000 | 500 | 260 |

B12.5 | 6250 | 6250 | 550 | 300 |

B15 | 7500 | 7500 | 750 | 500 |

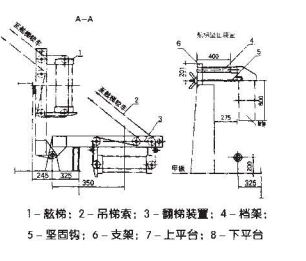

Marine Accommodation Ladder

- Material: Alluminum alloy

- Standard: ISO5488-2015,T14360-93

- Equipment: Fixed arc step,Antiskid groove

- Treatment: Anodic oxidation

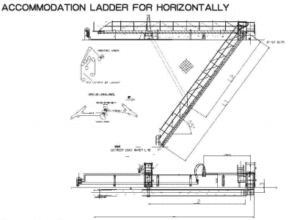

The types of our accomodation ladder: Accommodation Marine Gangway For Horizontally, Accommodation Telescopic Gangway

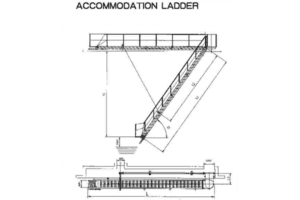

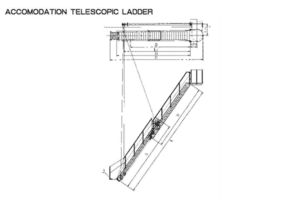

Accommodation Telescopic Gangway

This Product in line with ISO5488-2015 and GB/T14360-93 standard design, manufacturing of aluminum ladder. The structure is strong, safe and reliable, can meet the requirements of various ships and ship operation requirements. The product adopts a fixed arc step, the surface is provided with an anti-slip groove, and is anodized for good anti-corrosion performance.

NO. | Steps | L | A | B | L2 | D | E |

30 | Lv30 | 9000 | 5000 | 5500 | 8050 | 8550 | 8000 |

35 | Lv35 | 10500 | 5750 | 8250 | 8700 | 7200 | 8750 |

40 | Lv40 | 12000 | 6500 | 7000 | 7550 | 8050 | 9500 |

45 | Lv45 | 13500 | 7250 | 775 | 8300 | 8800 | 10250 |

50 | Lv50 | 15000 | 8000 | 8500 | 9050 | 9050 | 11000 |

~ | ~ | ~ | ~ | ~ |

Pilot Ship Gangway

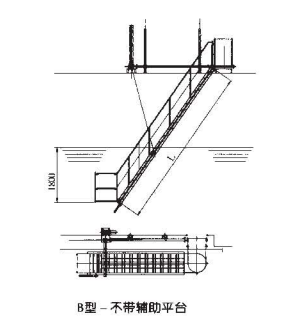

Accommodation Gangway For Driver

Type :

A with auxiliary platform

B without auxiliary platform

More than 28 pedals can be customized

Type Ladder length(m) Ladder Steps Max height(m) Deck layout dimensions(A) Deck layout dimensions(B) A B 3600 12 1.3 8100*500 8950*500 4200 14 2.7 8800*500 7450*500 4800 16 3.2 9100*500 7950*500 5400 18 3.6 9800*500 8450*500 6000 20 4.1 10100*500 8950*500 6600 22 4.8 10800*500 9450*500 7200 24 5.2 11800*500 10450*500 7800 28 5.8 12600*500 11450*500

Boarding Gangway

Type | Including | Applicable wharf /t |

EBL-E1 | Main gangway, triangular gangway, frame | 3000~30000 |

EBL-E2 | Main gangway, front gangway, triangle gangway, rotating platform, column | 5000~50000 |

EBL-E3 | Main gangway, front gangway, triangle gangway, rotating platform, traction mechanism, column | 10000~80000 |

EBL-E4 | Main gangway, front gangway, triangle gangway, rotating platform, traction mechanism, column | 20000~300000 |

Features:

- Aluminum alloy suspension ladder, variable step structure

- Hydraulic amplitude and rotation system

- Wireless remote control

- Various types are used to meet site conditions

Gangway For Boat Installation Inspection

1. Inspection of equipment before boarding

Check the marine product qualification certificates, physical steel stamps or marks of the marine aluminum gangway, pilot gangway, soft ladder and mechanical lift, gangway hanger and cross arm, hoist block and wire rope and conduct visual inspection.

2. Equipment installation inspection

Check the installation of equipment on board. After the gangway is installed, the installation and welding quality of the hanger cables, pulleys and related structural parts should be checked. The parts connected with the hull structure should be assembled correctly and welded firmly, and attention should be paid to preventing damage to the hull structure.

For the pilot’s gangway, it is to be checked whether it is installed on the straight part of the ship’s side and inclined to the bow direction, and its arrangement is to avoid the side drain. Make sure that the pilot gangway and boarding point on the outside of the ship are fully illuminated. In addition, it is to be checked whether the setting of bulwark doors meets the requirements of the drawings, so as to facilitate the boarding of the pilot.

Check the flexibility of the gangway, such as turning and turning over, and make a strength test. For new ladders: the gangway should be at an angle of 60° to the horizontal, and a load of 150kg should be placed on the odd steps and the lower platform of the ladder, and a load of 300 tons should be placed on the upper platform for 15 minutes. After the load is removed, the rotating parts of the gangway should be kept Flexible, each part should be free of defects or obvious deformation; for the repaired gangway: the gangway should be placed 0.5m above the summer load waterline, with a load of 75kg on each step or 150kg on every other step, and 150kg on the upper and lower platforms. load, lasting 30min in a static state, there should be no permanent deformation or other defects.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com