What Is A Gate Valve

Marine water gate valves is gate valve open or closed piece. The direction of the gate movement is perpendicular to the direction of the fluid. The gate valves can only be opened and closed fully, cannot be adjusted or throttled. Normally, the sealing surface on gate valves will be made of surfacing metal materials in order to increase the wear resistance, such as surfacing 1Cr13, STL6, stainless steel gate valve, etc. Depending on the type of gate, it is divided into rigid and elastic gate valves.

Cast iron gate valve is constructed of cast iron, cast steel, and cast copper. It is suitable for applications requiring low flow resistance and low medium pressure, as well as large diameter pipelines for seawater, freshwater, fuel oil, and lubricating oil.

Our Marine Gate Valves types for Sale

Wedge steel gate valve

This production has reasonable structure, reliable sealing, excellent performance and beautiful appearance. The valve clack and sealing surface of valve seat are made by resurfacing welding of iron-based alloy or Stellite cobalt-based alloy, which is wear resistant, high temperature resistant and corrosion resistant, it also has long service life.

The components of Ship gate valve

Name | Body, bonnet, bracket | Disc | Stem | Seat | Sealing ring Gasket | Packing |

Materials | WCB ZG1Cr18Ni9Ti ZG1Cr18Ni12Mo2Ti ZGCr5Mo | 2Cr13 304,316 Cr5Mo | 2Cr1,304, 316, 25Cr2MoV | 25, 304, 316 | 304 Coated mat | Reinforced flexible graphite |

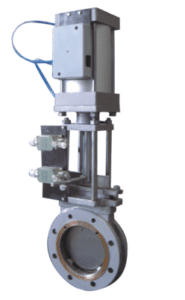

Wedge steel electric gate valve

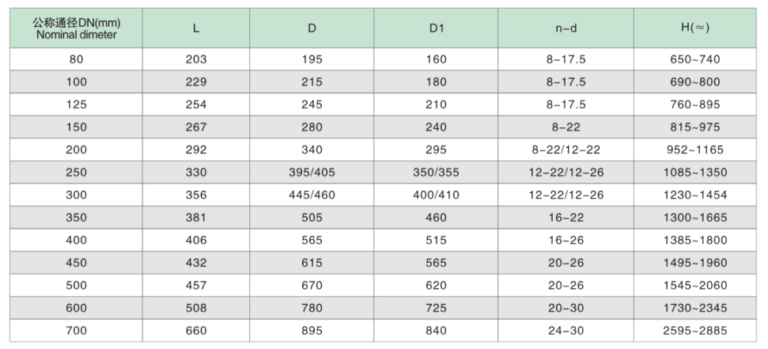

Knife-type ship gate valve

This production is wafer, flange direct knife-type gate valve, there is no retention recessed cavity; the valve stem has rising stem, non-rising stem and U-type sealing structure, it also has both of soft sealing and hard sealing, and the sealing is reliable. It has short structure length and light weight, so as to be installed easily. This production is suitable for industries of papermaking. coal mine, waster water, mud, sugar manufacture and slag, etc. the driving modes are: manual operation, bevel gear, air-powered and power-driven, etc.

The components of Knife gate valve

Body and cover Valve plate Valve stem Sealing surface Stainless steel, carbon steel, gray cast iron Carbon steel, stainless steel Valve stem Rubber, ptfe, stainless steel, hard alloy

Cast iron wedge gate valve

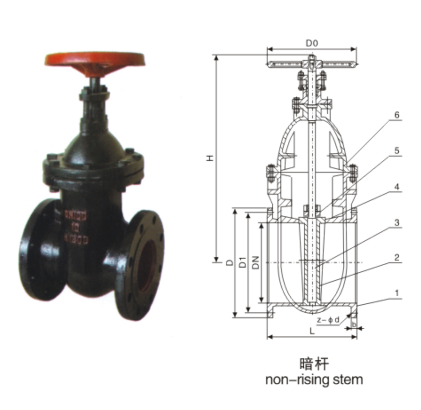

- Rising stem cast iron wedge gate valve

- non-rising stem cast iron wedge gate valve

This production is suitable for pipes and equipments of liquid and gas mediums, which is used for connecting and cutting off.

This cast iron wedge gate valve is mainly used for closure in pipe, whose installing is unrestricted by flow direction. Because the transmission mode takes power-driven, so a bigger torque can be transmitted while hoisting, in order to greatly lighten the strength of opening and closing.

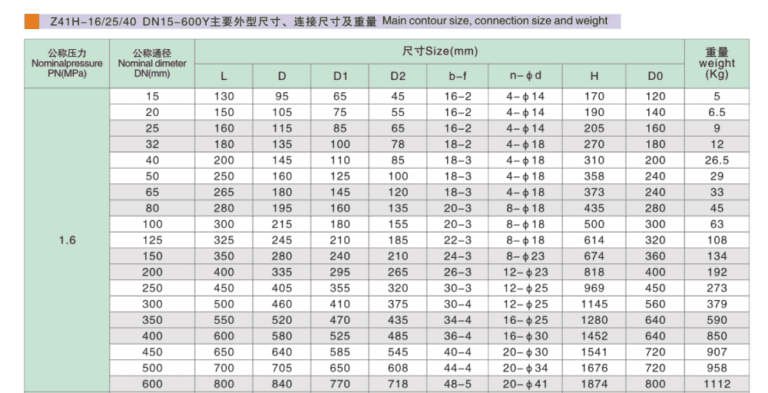

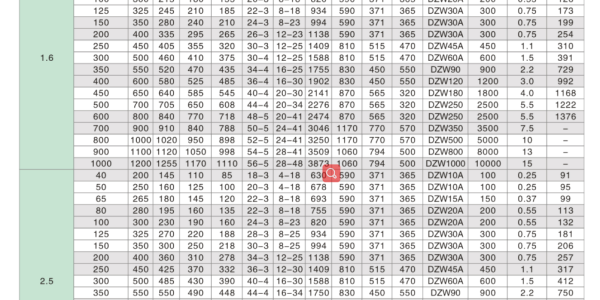

Major performance parameter

Nominal Pressure(MPa) | 1.0 | 1.6 |

Suitable temperature(℃) | <200 | <200 |

Applicable medium | Water, oil, gas and non corrosive mediums | |

main material | Gray cast iron, brass, chrome-plated carbon steel, stainless steel, Teflon | |

Perform standard | GB/T12232-89 | |

Test standard | GB/T13927-92 | |

How Does a Gate Valve Work

Marine gate valves have a wedge-shaped gate and a box-shaped valve body. During closing, the protruding part of the side surface seals, guides, and prevents swing.

There are trapezoidal threads on the lower end of the valve stem, tapered threads on the upper end, and a stop shoulder in the middle. In the gate, the upper thread meshes with the valve opening and closing indicator, while the lower thread meshes with the square nut. The valve stem rotates when the handwheel is turned. Due to the restriction of the middle stop shoulder, the valve stem cannot be moved upward or downward. Gate valve open or closed the medium passage, the gate plate is moved up and down along the valve stem by the square nut.

Features of Marine Flanged Gate Valve

- According to the design, the flange gate valve’s surface is fully coated with top-quality rubber, which results in the valve’s high flexibility, long service life, and zero leakage.

- At the bottom of the valve body, the non-groove has a small local resistance, preventing water leakage and dirt accumulation damage.

- Spraying the cavity of the valve body prevents corrosion and incrustation after long term use, preventing secondary pollution, so it is environmental protection and pollution-free production.

- The gatevalve does not need to be unloaded from a pipe in use, allowing quick online maintenance.

- Installing it is easy. As well as being suitable for constrained spaces, it is also widely used for foodstuffs, medicine, plumbing work, architecture, and fire fighting, etc, and is highly regarded by users.

Advantage of Our Boat Gate Valve

- By casting blanks with high precision, small deformations, and good appearance quality, but also by having a dense internal structure and good metallography, a valve’s service life can be extended.

- Using advanced production equipment, to ensure valve sealing face accuracy with angle finish and matching sealing pair requirements.

- Assembly equipment is advanced, and the personnel are excellent. Pressure seals are tested before leaving the factory for performance and quality.

- Gate valves have the following advantages over globe valves: small size, short assembly length between flanges, low flow resistance of the medium, and installation direction is not restricted.

As a result, higher pressures cannot be applied to the sealing surface between the gate plate and the valve seat in the gate valve because it is difficult to manufacture and easy to wear.

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com