Marine Gear Pump

Marine gear pump is a type of positive displacement pump commonly used in marine applications to transfer fluids such as fuel, oil, and water. It consists of two or more gears, typically meshed together, within a housing or casing. The gears rotate, creating chambers between their teeth, which trap and move the fluid from the pump’s inlet to its outlet.

Marine gear pumps are known for their ability to provide a steady flow of fluid at a constant pressure, making them suitable for various tasks on boats and ships. They are often used for transferring fuel from storage tanks to engines, circulating lubricating oil, transferring water for cooling systems, and other fluid transfer applications.

Marine gear pumps are available in different sizes and capacities to accommodate various flow rate requirements. They can be driven by an electric motor, a diesel engine, or other power sources commonly found on marine vessels.

Ship Gear Pump Types

There are several types of marine gear pumps commonly used in marine applications. External gear pump consist of two meshing external gears that efficiently transfer fluid. Internal gear pum feature an external gear and a larger internal gear that work together to smoothly transport fluids. Gerotor pumps utilize an outer rotor with internal gears and an inner rotor with external gears to provide high efficiency. Lobe pumps, with rotating lobes creating fluid chambers, are ideal for handling viscous or shear-sensitive fluids. Vertical gear pump offers a compact design with a vertical drive shaft, making them suitable for space-limited marine environments.

Our Marine Gear Pump For Sale

Marine Gear Oil Pump

KCB, 2CY, YCB Series Marine gear oil pump applies to deliver non-corrosive lubricating-oil or equivalent liquid without solid particles and fibers at temperature below 300℃ and with the viscosity of 5×10-6~1.5×10-3m2s (5-1500cSt). Reducing the speed, the pumps can delivery the liquid that the viscosity can be up to 5×104cSt.

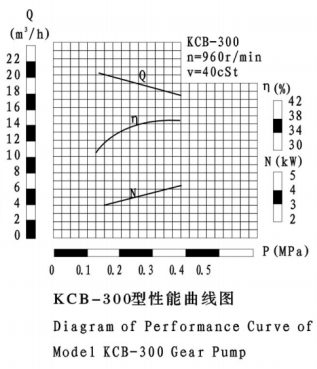

Oil gear pump performance curve

Performance data of all gear pumps have been defined on basis of the viscosity of 4×10-5m2/s(40cSt). The data indicated in the performance diagram is suitable to medium viscosity of 1×10-5~ 8×10-5m2/s(10—80cSt). If which exceeds the above viscosity, the data will be re-defined according to the client’ s demands. The given exhausting pressure of all marine gear pumps is the highest working pressure, and pumps can perform normally within range of the rated working pressure, which can be found in Diagram NO.1.

YCB-G Model Heat Insulating Gear Pump

The heat insulating gear pump is a type of external gear pump. It features a tooth form that combines arcs and sine curves, allowing for efficient and steady transfer of various fluids with consistent output flow and pressure.

The pump casing is equipped with a heat insulating jacket and inlet and outlet joints, enabling the use of heat-conducting oil, steam, hot water, or cold water to heat, maintain warmth, or cool the transferred medium and the pump itself. It is important to note that when dealing with highly viscous fluids with a viscosity exceeding 1500cSt, it is recommended to reduce the pump speed to ensure optimal performance. This heat insulating gear pump is designed to provide reliable and controlled fluid transfer while accommodating different temperature requirements for the transferred medium.

Structure Drawing of Heat Insulating Pump

1. Back cover 2. Pump casing 3. Gear 4. Bearing stand 5. Bush 6. Front cover 7. Seal ring 8. Driving shaft 9. End cover 10. Driven shaft

WCB Series External Lubricating Gear Pump

WCB series external lubricating gear pump is a new type marine gear pump developed by our company according to the market demand.

It is maily used for transportation of high-pressure foan liquid without lubrication characteristic in affiliated equipment for fire fighting.

- This marine pump provides such virtues as high pressure, anti corrosion, stable transportation of mediums, low vabrition, low noise, good appearance and long service life etc.

- It is applicable for transportation of corrosive mediums without lubrication function.

- The applied temperature shall be not higher than 300℃.

- The pressure shall be not higher than 1. 2MPa.

WCB Series Performance Data

Model | Port(mm) | Capacity (m3/h) | Differential Pressure(Mpa) | Speed (r/min) | Motor Power(Kw) |

WCB8/1.2 | 65 | 8 | 1.2 | 970 | 7.5 |

WCB10/1.2 | 65 | 10 | 1.2 | 970 | 11 |

WCB15/1.2 | 80 | 15 | 1.2 | 720 | 15 |

WCB20/1.2 | 20 | 1.2 | 970 | 15 | |

WCB25/1.2 | 25 | 1.0 | 970 | 18.5 | |

WCB28/1.2 | 28 | 1.0 | 970 | 22 |

LYB ARC vertical gear pump

The LYB ARC vertical gear pump is designed with a focus on delivering reliable performance, quiet operation, extended lifespan, and excellent efficiency. It is capable of operating steadily and quietly while providing a long service life. Additionally, it ensures high efficiency in its pumping operations.

In terms of temperature, the vertical gear pump is suitable for environments with a maximum temperature of 50℃, while its maximum recommended usage temperature is 80℃. This allows for flexibility in various operating conditions.

For shaft sealing, the LYB ARC vertical gear pump utilizes mechanical sealing as its standard sealing method. However, it can also be equipped with a packing seal based on customer requirements. Additionally, for specific needs, options such as magnetic force drive and zero-leakage structure can be selected to meet specialized sealing requirements.

NYP Series Internal Gear Pump

NYP series internal gear pump is a kind of new positivel displacement pump. It is designed according to the different fields requirements of petroleum, chemical industry, paint, medicine, foodstuff and so on.It widly applies to a variety of mediums with different property and viscosity because of special structure and selected different pump’s materials.

- Proper medium Temperature: -10℃~200℃

- Proper medium viscosity: 1. 0cSt-300, 000cSt

Internal gear pump performance curve

Instant Quote Online

Dear friend, you can submit your pressing need online, our staff will promptly get in touch with you. If you have any questions, consult our customer service through online chat or telephone in a timely fashion. Thank you for your request online.

[86] 0411-8683 8503

available from 00:00 – 23:59

Address :Room A306, Building#12, Qijiang Road, Ganjingzi

Email : sales_58@goseamarine.com