Smoke Detector to Singapore

The customer has a modern fleet of about 55 ships, ranging in size from 4200 tons to 35000 tons. The customer has worked with us several times. They purchased a marine smoke detector from Gosea marine this time.

The customer has a modern fleet of about 55 ships, ranging in size from 4200 tons to 35000 tons. The customer has worked with us several times. They purchased a marine smoke detector from Gosea marine this time.

On August 5, 2021, Gosea Marine won an order to provide container fittings and lashing equipment for this Singapore container ship. The contract with us is the ship operator of the ship.

Gosea marine is entrusted by the ship management company to provide a new water box cover for this bulk carrier. Especially before that, the customer has cooperated with us several times and purchased ship valves, pumps, ship cranes and other equipment from the factory.

On the way to Singapore, the cabin ballast system had some faults, and the container fasteners needed to be replaced urgently. When customers contact us, they know that we are a manufacturer specialized in providing ship parts, with our own factory and specialized engineers to provide parts solutions. Therefore, they chose to cooperate with Gosea Marine

The customer has hired a reputable maintenance company to overhaul his ship. However, they realized that more fasteners were needed to ensure the safety of the container, so they contacted us, our professional ship parts engineer, to provide the best solution for customers’ ship parts.

A carry deck crane is a type of crane that has a deck or platform on which loads can be carried. These cranes are typically used for construction and industrial applications.

A deck crane is a type of crane that is commonly used on ships. Deck cranes are used to lift and move cargo, as well as to place and remove containers from the ship.

Container lashing is the process of securing cargo within a shipping container. This is typically done using rope or webbing, which is threaded through anchor points on the walls of the container. The cargo is then tied down, so that it doesn’t shift during transport

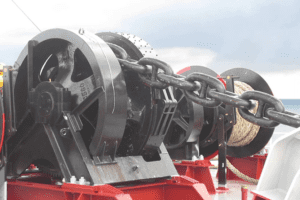

The windlass is mainly composed of base, bracket, chain wheel, brake, chain wheel, gearbox, electric control system (except manual windlass), etc. Electric windlasses have electric motors, and hydraulic windlasses have hydraulic pump stations.

Room 206,Sanhe Building, Donglian Road, ShaHeKou District

Dalian, LiaoNing, China

Tel: +86-411-86838503

Fax: +86-411-86807153

Mail: sales_58@goseamarine.com