It helps to ensure the precise navigation of marine operations to learn about various types of marine wire rope and think about several factors like materials, strength, and environmental circumstances. Whether you want to fix ships, tow cargo, or even secure facilities, it is vital to choose an appropriate kind of steel rope for sale. This approach helps to maintain security and efficiency.

Types Of Marine Wire Ropes

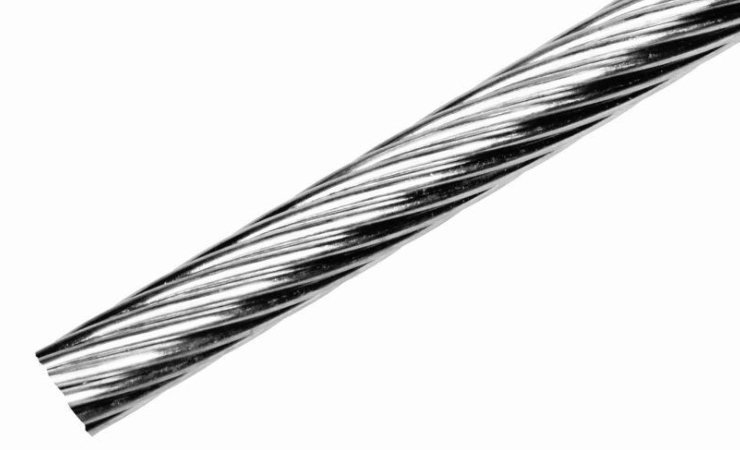

Marine wire ropes are prevalent among various maritime applications. That’s driven by their properties of strength, durability, and resistance to terrible marine environments. Commonly, there are some typical types of ship wire ropes in marine applications:

Stainless Steel Wire Ropes: These ship wire ropes possess extreme resistance to corrosion. That’s the reason about their suitability of the seawater. Thanks to their durability and sturdiness, they are useful in some specific applications.

Galvanized Wire Ropes: They are covered by a layer of zinc to protect them against corrosion. Galvanized wire rope is commonly used in marine environments. In these conditions, corrosion resistance is essential. But obviously it is not as critical as that in stainless steel wire ropes.

Vinyl-Coated Wire Ropes: Vinyl-coated wire ropes are coated with a layer of vinyl or other synthetic materials. This coating offers extra protection against corrosion and abrasion. That makes them more suitable for marine applications needing the protection of the underlying wire.

Dyform Wire Ropes: Dyform marine wire ropes are constructed using a compacted strand design that enhances strength and stability. They are commonly used in marine applications where high strength and minimal stretching are required.

Non-Rotating Wire Ropes: Non-rotating wire ropes are designed to prevent twisting and rotation under load. They are commonly used in marine applications where stability and control are crucial, such as crane operations.

Plastic Coated Wire Ropes: Plastic-coated wire ropes are covered with a layer of plastic material for protection against corrosion and abrasion. They are used in various marine applications where a durable and protective coating is necessary.

The Core Types Of Marine Wire Rope

There are diverse core constructions in various marine wire lines, and those may influence their strength, flexibility, and durability. Typically, some common types of core in ship wire ropes include:

Fiber Core (FC): Fiber cores are made of natural or synthetic fibers like sisal or polypropylene. These materials are home to outstanding flexibility. This property is highly suitable for applications needing to consider bending fatigue. Fiber cores provide a cushioning effect, and that reduces abrasion of the outer strands of the marine wire rope. They are light and economical so that they are suitable for general marine applications requiring flexibility.

Independent Wire Rope Core (IWRC): IWRC consists of a separate wire strand core that serves as the central foundation of the steel rope for sale. This core type enhances the overall strength and stability of the wire rope. IWRC cores are known for their high fatigue resistance, making them suitable for applications that involve frequent bending or heavy loads. They offer superior crush resistance and are commonly used in marine operations that require high strength and durability.

Wire Strand Core (WSC): There is a wire strand in the center of wire strand cores, and the outer strands are placed around the central strand. The design provides higher strength and stability than the fiber ones. WSC possesses outstanding capabilities against pressure and deformation, and that promotes it to be the ideal option in demanding marine applications under conditions of high loads and harsh environments. As it is commonly used for maritime operations, it is needed to be reliable and durable.

Fiber Core with Steel Wires (IWFC): It combines the flexibility of a fiber core with the added strength of steel wires laid around the core. This construction provides a balance between flexibility and strength, making IWFC cores suitable for applications that require both qualities. IWFC cores offer good fatigue resistance and strength, making them ideal for marine crane operations where flexibility and durability are essential.

Optimizing Wire Rope Selection for Marine Applications

Selecting the types and core constructions of marine wire lines helps to maintain optimal performance and security in marine applications. Some guidelines about how to combine core types with rope types according to the specific marine applications are as follows:

For heavy-duty marine lifting operations requiring high strength and durability, a stainless steel marine wire rope with an Independent Wire Rope Core (IWRC) is an excellent choice. Stainless steel provides corrosion resistance, while the IWRC enhances stability for lifting heavy loads in harsh marine conditions.

In general marine rigging and mooring applications, a galvanized wire rope with a Fiber Core (FC) offers a good balance. The galvanized coating protects against corrosion, and the fiber core provides flexibility, making it suitable for rigging and mooring tasks on boats and docks.

For marine cable railing systems and boat lifelines, consider using a vinyl-coated wire rope with a Wire Strand Core (WSC). The vinyl coating adds protection against corrosion and abrasion, while the WSC core provides strength and stability for railing systems and lifelines.

In marine crane operations that require a balance between strength and flexibility, Dyform wire ropes with a Fiber Core with Steel Wires (IWFC) are a suitable choice. Dyform ropes offer high strength and low stretching, while the IWFC core provides the necessary balance of flexibility and strength for lifting heavy loads.

For offshore drilling operations and marine winches where twisting under load must be minimized, Non-Rotating Wire Ropes with an IWRC core are ideal. These ropes provide stability and control, while the IWRC core enhances strength and fatigue resistance for demanding offshore applications.