What Is A Marine Valve?

Marine valve is an essential device designed to control the pressure, flow rate, and flow directions of fluids in pipelines so that it can meet the demands of environmental conditions. Marine stopcocks are the control equipment of fluid pipelines, and they have various basic functions, including connecting or cutting off the circulation of the medium, changing the circulation rate and directions of the medium, adjusting the medium’s pressure and rate, and maintaining the normal operations of pipelines.

Types of Marine Valves

Marine valve is the key component to control fluid flow in marine systems. There are many kinds of them, and each kind has its own unique operation mode and applicable conditions.

Sluice Valve

The switch is realized by the vertical movement of the gate, which has the characteristics of full-diameter circulation and low-pressure loss and is suitable for large-diameter seawater/freshwater pipeline systems. Common open poles (visual operation) and hidden poles (concealed installation) are made of cast iron.

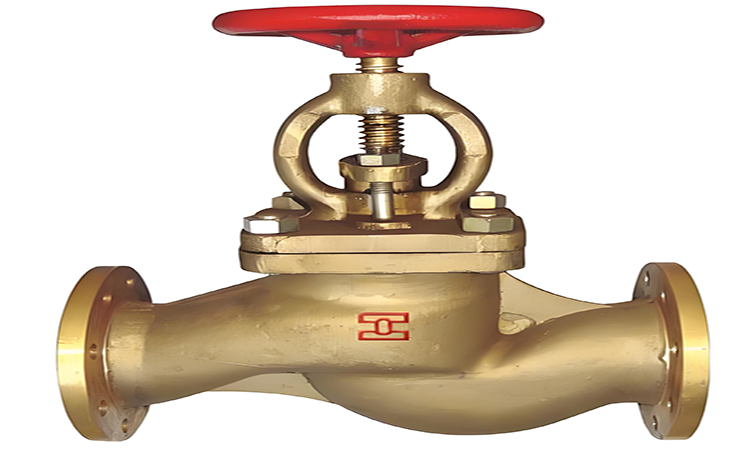

Stop Valve

The flow rate is accurately controlled by the linear motion of the disc, and the sealing performance is excellent. The stop valve is often used in freshwater systems, steam systems and other scenes that need accurate adjustment. Including straight-through, straight-through, angle, and plunger. For example, the plunger globe valve is designed with an elastic sealing ring, which is suitable for frequent switching operation.

Butterfly Valve

The rotating butterfly valve is used to control the fluid, which is compact in structure and convenient to operate, and is suitable for seawater cooling and ventilation systems in medium and low-pressure systems. Typical applications include fire pump piping.

Ball Valve

Fast switching is realized by rotating the ball, which has outstanding sealing performance and is mostly used in fuel transportation and hydraulic systems. Its processing accuracy is high and its cost is relatively expensive.

Check Valve

This kind of valve includes a lifting type and a swing type. One-way control is realized through the flow of the medium itself to prevent backflow. Core applications include seawater pump outlet and fuel pump outlet protection. For example, the silencing check valve reduces the closing noise through a special structure.

Application Field of Marine Valves

Application in control system

In the control system of the ship, ship valves play a key role in regulating and cutting off the fluid. Whether it is a cooling water system or a hydraulic system, the valves can accurately control the flow and pressure of the fluid. For example, in the cooling system of the main engine, by adjusting the opening of the valve, the flow of cooling water can be controlled to ensure that the main engine runs at a suitable temperature. In addition, in the hydraulic system of steering gear, the valve is used to control the flow direction and pressure of hydraulic oil, so as to realize precise control of steering gear.

The application in the power system

Marine valves also play an important role in the marine power system. The precise control of valves is indispensable in fuel system, lubricating oil system, and exhaust system. In the fuel system, the valve is used to adjust the supply and pressure of fuel to ensure the stable operation of the engine. In the lubricating oil system, the marine stopcock controls the flow direction and quantity of lubricating oil to maintain good lubrication of engine parts. In the exhaust system, the valve is used to regulate the emission of exhaust gas, protect the environment, and ensure the efficient operation of the engine.

The application in the hull structure

In addition to the above two kinds, marine valves for sale are also widely used in places where fluid control is needed in hull structures. For example, in the ballast water system, valves are used to control the entry and exit of ballast water to maintain the stability and buoyancy of the ship. In the fire fighting system, the valve is used to control the flow direction and injection of fire extinguishing agent to ensure that the fire can be extinguished quickly and effectively in an emergency.

Some Suggestions on Selecting Marine Valves

Sealing: The sealing performance of the marine valve is directly related to the safety and efficiency of the ship system. High-quality sealing materials can ensure the valve maintains a good sealing effect during long-term use and prevent liquid or gas leakage. Therefore, when purchasing, we should carefully check the sealing material and design of the valve and its ability to cope with high-pressure and high temperature conditions.

Corrosion resistance: Seawater has seriously eroded the valve, so the material of the ship valve has an important influence on its performance and life. According to the specific purpose and working environment of the ship, it is very important to choose suitable materials. For example, in a corrosive marine environment, valves made of materials with high corrosion resistance, such as stainless steel or special alloys, should be selected.

Ease of maintenance: The maintenance of the ship valve is the key to ensure its long-term stable operation. When purchasing, the convenience of valve maintenance should be considered, including the difficulty of disassembling, cleaning, and replacing parts. Choosing a marine valve for sale with a reasonable design and easy maintenance can reduce the later maintenance cost and time.